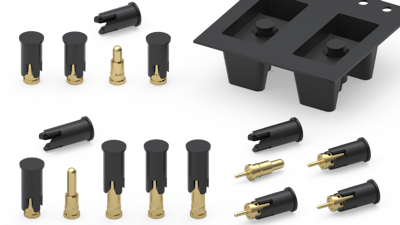

Mill-Max's new spring-loaded pins with removable pick and place caps for automated assembly.

Mill-Max

Mill-Max (Oyster Bay, NY) has announced a new option for automated assembly of spring-loaded pins with the introduction of removable pick & place caps. The new 806 series features standard spring pins with removable caps that keep parts centered in the carrier tape pocket, present a large round target surface for vacuum pick up, and are easily removed after the soldering process. Additional features of the 806-22-001-30-0XX191 series include:

- Applicability when production volume necessitates automatic assembly yet an insulator is not required or feasible.

- Removable caps that attach to the body of the spring pin, slipping over without compressing or damaging the plunger.

- A four-finger design that makes the cap easy to remove.

- A closed flat top that ensures reliable vacuum pick up every time.

- Availability in 9 surface mount options using standard Mill-Max spring pins 0900-X and 0907-X.

- 4 through-hole style spring pins.

- Parts packaged per EIA-481 standards on 13” reels with the surface mount style on 16 mm wide tape and through-hole on 24 mm wide.

- Removable caps made of high temperature nylon 46 that are suitable for most soldering processes.

- Precision-machined external components and high reliability internal springs.

- Gold-plated components and springs that ensure conductivity, corrosion resistance and durability.

- Spring-loaded pins with a current rating of 2 A continuous use (3 A max).

For more information, visit: www.mill-max.com; or call 516-922-6000.