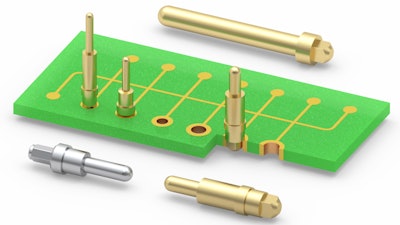

Mill-Max (Oyster Bay, NY) has added to its mix of press-fit pins with six new offerings designed for applications where mechanical strength and/or power delivery are essential (see chart in gallery). The new PCB pins feature multi-faceted (polygon) geometries and are suitable for solderless PCB termination or for direct soldering to the board for those situations requiring it.

When the pins are pressed into a plated through-hole, the points (the major or circumscribed diameter) of the polygon are set or imbedded in the hole while the flat sides of the feature (minor or inscribed diameter) provide relief, allowing the remainder of the plated through-hole barrel to remain intact. Additional features include:

- Internal board layers are not disconnected when the pin is pressed in.

- The polygon shaped press-fit feature will allow the pin to be secured in the hole while maintaining continuity throughout all the layers of the PCB, with a properly specified hole size.

- Suitability in applications with more demanding mechanical/electrical requirements, such as power supplies, power converters and any device subject to blind mating or rough handling.

- Staked into a PCB at the press-fit end and either soldered or plugged in at the pin end.

- The smallest pin diameter in the group is .040” while the largest is at .080”, typical sizes for DC-DC converters.

- Pin material typically made of brass, but tellurium copper is also available.

For more information, please visit www.mill-max.com/PR673.