Musashi AI

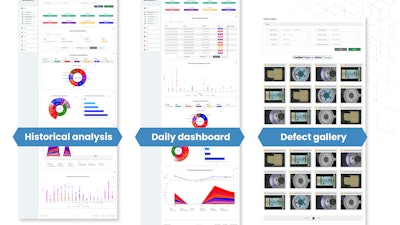

Musashi AI (Waterloo, Ontario) introduced updates to its Cendiant Inspect AI software and the Automated Shaft Inspector at Automate 2025 in Detroit.

Cendiant Inspect includes a new surface inspection model designed to detect chatter defects on camshafts and similar parts. These defects result from grinding machine vibration or tool imbalance and can affect part quality.

Features:

- Detects chatter defects that are difficult to identify visually

- Provides results comparable to dedicated optical shaft measurement systems

- Eliminates need for separate optical measurement machines

- Reduces waste and rework in part production

- Enables feedback through a ticketing system for reporting anomalies and system changes

- Adds chatter inspection capability as module to the existing Automated Shaft Inspector

- Suitable for automotive manufacturing applications

- Applicable to high-volume industries including electronics, consumer goods, oil and gas, food and paramedical sectors