As a contract manufacturer for some of the largest CPG companies in the U.S., when LiDestri Food and Drink goes looking to buy raw materials, more often than not we’re looking to place a large—and probably standing—order. But we can’t always find exactly what we’re looking for on behalf of our customers or our own proprietary brands.

Often, its more than a scarcity of materials that stalls our efforts. Supplies might not meet our quality requirements, be too costly or are not differentiated enough to fuel a unique product on the shelf.

Sustainability is another growing concern for consumers, and therefore for manufacturers as well. For all of these reasons, we are always exploring new and inventive ways to shorten or vertically integrate our supply chain.

The strategy has its pros and cons.

As the Wall Street Journal noted in a March story: “Vertical integration gives companies more control over critical elements of their supply chains, but it also places new demands on corporate leaders as they address questions of how far their companies can go in overseeing all stages of production.”

Yet the production of fresh basil, craft whiskey and organic tomatoes are all new projects we’ve chosen to assume at LiDestri so we can produce the finest, and most successful, products possible. Each of these examples demonstrates a different impetus for vertical integration in supply chain management and a creative solution to get the job done.

Craft Whiskey in High Demand & Short Supply

An explosion of demand for high quality craft spirits, most notably subtly balanced brown varieties such as bourbons and ryes, has put distilleries on a growth curve that is even steeper than that of the craft beer craze in the 1980s, noted Pennfield Jenson, founder and executive director of the American Craft Spirits Association (ACSA), in Marketwatch. The same article noted that the craft spirits industry is growing at an annual 30 percent clip, citing the American Distillery Institute.

LiDestri has a large spirits portfolio, but we wanted in on craft whiskies, and especially bourbons. But because aging is an important part of the bourbon-making process, we needed to find a partner who was already in the game. Our search ended fortuitously, in our own back yard of Fairport, NY, with nearby Iron Smoke Distillery.

Our investment will help Iron Smoke quickly ramp up production of its namesake applewood-smoked Iron Smoke bourbon, which is aged 18 to 20 months in virgin American oak, as well as its unaged counterpart, Rattlesnake Rosie’s Apple Pie Whiskey. Iron Smoke’s award-winning, “dangerously drinkable” whiskey and bourbon will soon become more plentiful and widely available as a result of our partnership.

Organic Tomato Varietal Offers Differentiation

At the low priced end of the spectrum, tomato and other pasta sauces have become increasingly commoditized, squeezing profit margins. Meanwhile, at the super-premium end producers are increasingly looking for ways to differentiate their products and elbow into the profitable specialty market.

So when one of our longest-standing customers, Newman’s Own, wanted to create the best tasting organic pasta sauce on the market, we got creative. For us to fulfill their request, we had to find a California grower who could plant and harvest 1.5 million pounds of a super-flavorful tomato varietal, which was selected in a taste test where it beat out Italy’s famed San Marzanos.

Thanks to its flavor profile, and the organic practices we implemented at every facet of the production process, the Common Good sauce line stands out on the shelf for its exceptional taste, quality and economy.

Homegrown Basil Farm Assures Quality and Quantity

As consumers are demanding healthier and natural foods, our customers are asking us to improve the quality of the ingredients in their products. Given the fact that much of our business is in pasta sauces, our need for fresh, high-quality basil is already considerable and constantly growing. In recent years, we’ve found ourselves trying to cobble together sufficient orders from multiple suppliers and growers in various countries, but have occasionally been less than satisfied with the quality.

After evaluating every option, we decided the most effective supply chain solution for us is to grow and harvest our own basil in a climate-controlled hydroponic warehouse-farm, where we can control quality and the supply stream. Currently, we are in the initial phases of promising trials that have been designed to achieve optimal results.

Evermore-demanding consumers and always-increasing competition has made navigating and mastering the supply chain in today’s food and beverage business more complex, yet more important, than ever before. Successfully mastering vertical integration improves our product quality, price points and bottom line at the same time it fulfills customer needs.

Most significantly, we have found that viable solutions for successfully mastering vertical integration requires some combination of strategic partnerships, commissioning or otherwise incentivizing suppliers—and sometimes plain old just doing it yourself.

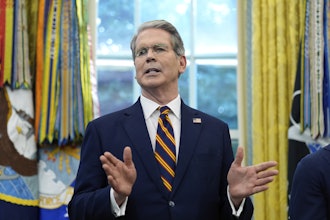

John C. LiDestri is Co-President of LiDestri Food and Drink, overseeing both sales and supply chain. A partner in National Cortina for the past 16 years, he has a lifetime of experience in ingredient sourcing on behalf of some of the country's largest and most dynamic food and beverage manufacturers.