Although most manufacturing employees are trained in preventative safety measures, it’s all too easy for trained and skilled workers in the industrial sector to get hurt on the job. The number of workers who are seriously injured or even killed while using machinery is staggering.

Every year, more than 34,000 workers sustain an injury due to machine accidents and more than 11,000 experience severe lacerations while conducting daily work. Meanwhile, on average, more than 99 workers per week or 14 each day die on the job. Obviously, workplace safety continues to require the prompt attention of everyone charged with ensuring it.

Not only is the prevalence of workplace injuries alarming from a human resources perspective, but also it’s bad for business. When people are injured due to accidents at work, they end up needing time off. This can result in a company’s costs going up while productivity goes down. So what can managers in the industrial sector do? What are the best ways for employees to work safely and sustainably with heavy equipment and machinery?

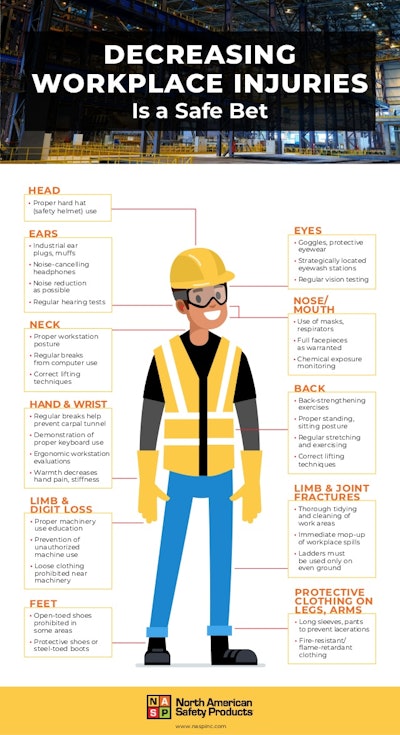

To help answer these questions, the infographic below provides a useful checklist of safety measures to keep in mind. It showcases tips that can make a big difference in minimizing harm to workers, such as the use of protective and flame-resistant clothing as well as respirators, goggles and noise-canceling headphones.

Check it out to learn more about what you can do to help prevent injuries in a manufacturing environment or around heavy equipment.

James Pfeiffer is CEO for North American Safety Products, a OEM specializing in safety and security equipment. He has more than 18 years of experience in the industrial product manufacturing industry.