There are many cases where an expensive torque sensor would be excessive for measuring torque and speed. R+W Antriebselemente has launched a completely new alternative with its intelligent coupling. The product innovation presented here allows recording measurement data directly in the drive train, while providing very accurate measurements and user-friendly operation.

Some of the objectives fundamental to the Industrial Internet of Things (IIoT) include the optimization of operational efficiency, cost-cutting in production, and monitoring equipment or machinery. Better data can assist in making major improvements in production processes and efficiency. Constant improvements in process reliability are possible with modern practices, such as predictive maintenance and artificial intelligence in machines. This cuts production times and enhances product quality.

Collecting data in the field of drive technology is not always a simple task. Recording measurement data in a rotating drive train is hampered by the fact that direct networking with a cable is either not possible or the installation space needed is lacking. R+W An-triebselemente is now offering a hardware and software solution that offers user-friendly, versatile deployment in the form of the intelligent coupling.

Tried-and-true mechanism with smart measurement electronics

The intelligent coupling is an upgraded version of the standard coupling that will also offer measurement technology functions. The integrated sensors will measure torque, speed, acceleration, axial force, and rotational position. This data is processed by internal electronics while being simultaneously transmitted and presented in a wirelessly connected mobile de-vice. At the same time, the mechanical properties of the coupling are not impaired by the integrated electronics, and the unit will provide for axial, lateral, and angular misalignment compensation.

Networked drive train

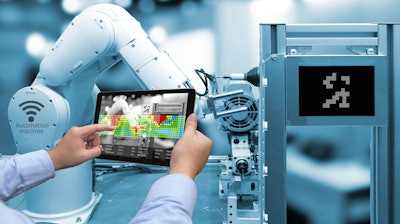

The intelligent coupling can be easily and flexibly integrated in the drive train. The installation options are not restricted by a permanent cable connection. Power supply from an integrated battery permits deployment in very tight spaces or remote application areas. The measurement data is transmitted in near real time via Bluetooth Low Energy connection to a smartphone or tablet with the installed R+W app. This connectivity option allows for of a high transmission rate of 500 Hz or especially low power consumption. Software on the mobile device shows the data as a mean value and with a min/max range in large, freely configurable views. Various scalable diagram types track the detailed trajectory of the measured data. For example, any number of measured variables can be presented on top of each other in the multi-graph. Measurement data of several couplings can also be graphically illustrated simultaneously in a diagram. The measurement data can be saved as a CSV file for further analysis and then imported into an Excel file.

Fast and easy recording of measurement data

R+W's intelligent coupling is a smart alternative to a torque sensor. It provides highly precise measurement of a variety of mechanical information at a low price. The intelligent sensors allow data measurements without having to install an external measuring amplifier. An additional advantage is the small amount of space needed for installation, since no elaborate auxiliary construction is required. Mounting an intelligent coupling in the existing drive train is fast and easy, and sensors can also be retrofitted into a pre-mounted coupling after installation.

For greater transparency in the drive train

Among other things, the combinable, time-dependent factors measured can be used to achieve better evaluation and transparency of dynamic behavior in the rotating drive train. Determining torque and forces can reduce or prevent outage and downtimes, improving system availability and reliability.

In 2020, even more models with integrated sensors will succeed the intelligent disc pack couplings, but the development will still be far from reaching its full potential. New functions and various algorithms for evaluating the data measured will ensure that couplings become even more intelligent, setting new standards on the market.

For more information, contact R+W America.