LED lighting technology has advanced rapidly over the last five years, with more form factors, higher lumen output and longer life performance, giving industrial facilities the most energy-efficient and cost-effective lighting solutions.

We now have LEDs that deliver equivalent lumen output to some of the most powerful HID fixtures, and do so at half the energy cost. In addition to the electricity savings, the maintenance savings alone can be a tremendous boon to the bottom line, eliminating bulb changes that consume personnel time and money.

With such rapid innovation in the industry, many are wondering, “What’s next?” Let’s take a quick glimpse into the LED technology roadmap and explore how the next generation of innovations will define the future of industrial LED lighting.

Performance and Efficiency

Probably the most important and followed advancement will be continued improvement in lumen output and lumens per watt (l/w). We’re already seeing LEDs in the market exceeding 200 l/w, and this will only continue to climb over the next 10 years to near the theoretical max of about 250 l/w.

This achievement will enable 200+ l/w light fixtures. We’ll also see continued improvement in color quality as 90 color rendering index (CRI) and higher become the norm. Along with a higher CRI, we’ll see the efficiency gap between neutral/warm and cool white LEDs close, as well as more color tuning options as manufacturers add in specific colored LEDs and optimize phosphors to tailor the color spectrum for specific applications.

Standardizing or Eliminating Packaging

Like other electronics technology, LED packaging has shrunk. It has become simpler and less expensive, which has dramatically reduced production costs and enabled a larger volume of LEDs to come to market and be more accessible to customers. Not only will we see this minimalist trend continue, but we may very likely see packaging virtually disappear completely, introducing what’s called chip-scale LEDs—simply the LED with solder pads underneath.

At the same time, LED manufacturers will arrive at a more standardized package design, making it easier for manufacturers to design fixtures faster and with more options based on standardized LEDs. This could be preferable to the current process of designing around the specialized package, electrical footprint and performance characteristics from each LED supplier. That also means a much faster time to market.

Fewer Parts

As LEDs become smaller and simpler, the fixture housings will also become smaller. They'll require less heat sinking and be made of lighter-weight materials like plastics for an overall lighter fixture that costs less to produce. Alongside this improvement, we’ll see reliability improvements emerge for the other fixture components, such as the power supply, paint/finish, and seals. This will give customers the confidence in bumper-to-bumper lifetime warranty where all materials and components last as long as the LEDs.

That will eventually lead to a lighting system without a need for replaceable parts, eliminating costly consumables, reducing labor and supply chain costs, and eliminating lighting-related disposal costs and landfill waste – a true solution to sustainability.

Controls Will Become Commonplace

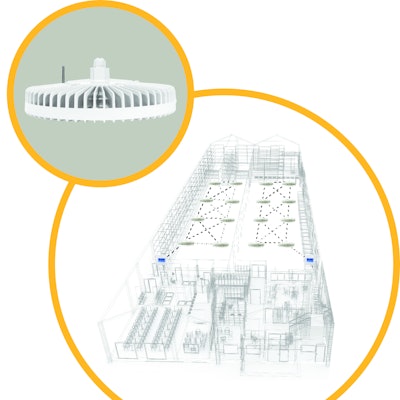

Not only will we see a proliferation of occupancy, dimming and daylight harvesting sensors and controls that will dramatically lower energy use, we will also see LED lights becoming more than just a light source through the use of advanced sensors and connectivity. For example, occupancy sensors can be used to monitor activity in specific areas to improve productivity and workflow.

Lighting Will Double as a Communications Network

Going forward, LED fixtures will offer wired or wireless connectivity for their own use in monitoring and controls, which can also be used to carry data for other devices as well — mobile phones, tablets, computers and manufacturing equipment. A new technology called LiFi is also on the horizon, using light from the fixture to transmit data.

With LiFi, high-frequency light pulses, which are not noticeable to the eye, can transmit data to other devices such as cell phones. For example, retailers could use LiFi to send promotional messages to customer phones, offering product info or discounts to shoppers at specific locations throughout the store.

New applications will expand industrial and commercial LED markets.

The trend toward urban agriculture and the use of UV LED lighting for polymer curing, as well as air and water purification, could dramatically improve efficiency, lower cost and improve access to cleaner air and water for millions of people.

In addition to the many advantages of LED lighting compared to conventional HID and other sources that contribute to a lower total cost of operation, LED also has one overwhelming advantage: room for innovation. Where conventional lighting technology hasn’t advanced much over the past five or 10 years, LED lighting has advanced by leaps and bounds.

As many who have already made the transition know, the future is very bright for LED lighting.

John Peck is the VP of Engineering, Optics & Mechanical Department at Dialight Corporation.