In this test, we flex.

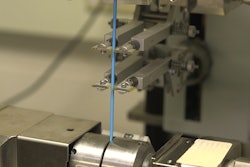

The flex test machine at Interpower's Ames, Iowa location is one of the company's first (and largest) pieces of test equipment. It has tested millions of flex cycles.

It tests plugs and connectors by flexing 10,000 times as power runs constantly through the components.

If a copper wire fails, the test automatically stops.

The test takes about 3 hours, al to make sure that equipment stays powered up despite the strain.

It also tests adhesion, to make sure the cord doesn’t get pulled from the plug.

It tests to two different standards:

- IEC60320 for connectors.

- IEC60884 for plugs.

This test saves time, so there are now surprises when the cord goes to agencies for approval.

It also saves lives.

The Testing Series covers how one American manufacturer is making sure that we stay safe and our products remain powered. It features the Top 6 tests every cord should go through before it finds a mate.

The series includes exclusive footage from Interpower’s state-of-the-art facilities in Iowa, as the tests were being performed.