A team of researchers from Colorado State University's Energy Institute has received a $1.2 million grant from the U.S. Department of Energy's Office of Energy Efficiency and Renewable Energy to look at making natural gas engines as efficient as diesel engines in the same class.

Specifically, the researchers will develop medium- and heavy-duty, on-road natural gas engines that are as efficient as traditional diesel engines often used in long-haul 18-wheeler trucks, garbage trucks and delivery trucks.

The research could result in cost savings and improve air quality. Currently, natural gas is a cheaper and cleaner fuel than diesel. Natural gas engines emit fewer carbon dioxide emissions that contribute to climate change, less particulate matter (PM) that can affect the heart and lungs and cause serious health effects, and fewer oxides of nitrogen (NOx) that contribute to ground-level ozone and smog.

For these reasons, the team is excited to join together with commercial partners Cummins Inc. and Woodward, Inc. to tackle this engine technology challenge. The team includes Associate Professor Daniel Olsen; Assistant Professor Bret Windom; and Professor Anthony Marchese, all in the Department of Mechanical Engineering.

"We are excited to get to work alongside respected industry partners like Woodward and Cummins to advance natural gas engine technology," said Olsen.

Cummins and Woodward, having worked on these problems for decades, will provide the team with practical hardware for testing and the capability to commercialize technology breakthroughs.

Cummins is building a single-cylinder, 2.5-liter natural gas engine to be used as a key research tool for the project. Woodward is contributing combustion, ignition, fuel delivery technology and advanced engine controls.

"As we look to provide solutions for commercial vehicles in a carbon-constrained world, natural gas will be an increasingly important option and discovering breakthroughs in spark-ignited natural gas engine thermal efficiency will complement the clean-diesel technologies on the market today," said Robin Bremmer, director of Advanced Alternative Fuels & Ignition Systems at Cummins Inc. "We look forward to collaborating with the very talented researchers from CSU as they utilize the excellent analytical and experimental capabilities located at the CSU Powerhouse Energy Campus."

The Energy Institute team is proposing to break down technological barriers, such as the knock and misfire limits, to optimize combustion and improve natural gas engine efficiency. The team plans to do this using a three-pronged approach. First, they will use a laser spark-ignited rapid compression machine (RCM), an experimental device that simulates a single compression stroke of an internal combustion engine, to study the chemical kinetics and combustion of natural gas. Second, they will use a Cooperative Fuel Research (CFR) engine to study how gas composition impacts end gas auto-ignition, the phenomenon that leads to engine knock.

Third, using lessons learned from the RCM and CFR engine studies, the team will develop engine models to direct the design of the combustion-related components in a specially built Cummins engine for final testing and system optimization. Woodward's advanced combustion, fuel delivery and state-of-the-art combustion control technology will also play a role. These contributions will enable sustained operation of controlled auto-ignition, minimizing knock margin conservatism.

"The CSU [rapid compression machine] is a unique device to test the auto-ignition characteristics of the wide range of components found in natural gas and is able to simulate the components of recirculated exhaust gas for knock suppression," said CSU associate professor Gregory Hampson, who is Woodward's sponsor on this project. "This level of research in a wide range of fuels has not been done before, and it will help with engine design and control."

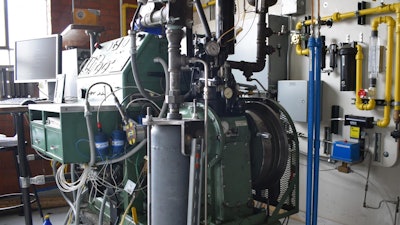

Olsen, Windom and Marchese all have offices and labs within the headquarters of the Energy Institute at the CSU Powerhouse Energy Campus. They share common research interests in engines, even though they are each experts on different sub-areas. The DOE grant gave them the opportunity to combine their expertise and work on a high-impact problem in their field. The team is set to begin work on the three-year project this summer.

"Collaboration works better here at the Powerhouse; it really is unique," said Olsen, adding that the physical engine testing lab spaces make it an ideal place to do innovative group projects.