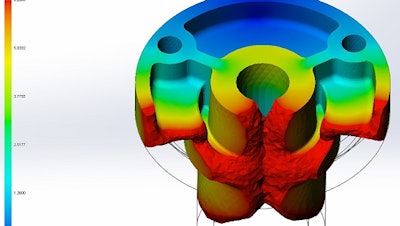

Haydon Kerk Motion Solutions (Waterbury, CT) recently added a powerful mold flow analysis software to help with the design of custom-molded lead screw and linear motion components. Solid Works Plastic Professional is an engineering tool used by Haydon Kerk’s experienced tooling engineers to help speed up the design process and offer customized solutions to fit customer’s application needs.

The use of mold flow analysis helps engineers run critical calculations to expedite the design of custom part and mold features, such as gate location, parting line location, design geometry, material flow, fiber alignment, vent locations, weld-line analysis, and cooling-line locations. All of these design considerations affect custom parts in the following areas:

- Ease in part strength.

- Reduction in part voids/improved fill.

- Reduction in cooling/cycle times.

- Reduction in material waste.

- Reduction in part warpage.

- Reduction in mold design/manufacturing time.

Haydon Kerk’s experience with the use of over 60 molded materials, including the Kerkite composites, PEEK and PPS base materials, combined with the capabilities of this new software, allows engineers to reduce the time required for the design and build process for custom molds. The combination of on-site tooling and molding machines also reduces the time to production for custom parts for existing Haydon Kerk polymers or customer-specified materials.

www.haydonkerk.com; 800-243-2715