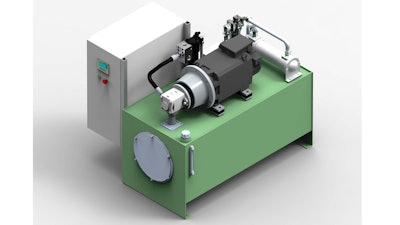

MJC Engineering (Huntington Beach, CA) has developed a new hydraulic power system, Green Hydraulic Power. The system provides higher machine yield, reduces noise emissions by 20 dBA, generates less heat, produces a shorter cycle time on various machine types and involves less oil volume, all resulting in a system that saves up to 70% in energy costs to reduce the user’s carbon footprint, according to the manufacturer. Additional features include:

- A Siemens SINAMICS variable speed servo pump drive.

- Applicability on all machine tools that use hydraulic power, including injection presses, materials handling equipment, stamping presses, and other metal forming machines.

- Control data output from the onboard diagnostic capability in the drive which supplies information for a predictive maintenance protocol in an Industry 4.0 scenario.

- Pressure, temperature and acceleration data measurement are standard, with additional data outputs available on oil level, filter condition, running efficiency and other parameters.

- A servo pump that results in as much as a 70% reduction in onsite servicing, according to the manufacturer.

- Availability in 100, 200 and 300-gallon tank units rated up to 4,000 PSI.

- Two styles: one with a VFD, asynchronous motor and internal gear pump, while the second has a servo inverter, synchronous servo motor and internal gear pump.

MJC has developed a subsidiary unit, Green Hydraulic Power, Inc. and separate sales force for the unit’s development in the market.

For more information, visit www.mjcengineering.com, www.greenhydraulicpower.com; or call 714-890-0618.