With extreme oil and gas supply shortages looming ever closer and the Strategic Petroleum Reserve of the United States reaching its lowest level in 38 years, the equipment used in the oil and gas industry must run as smoothly as possible.

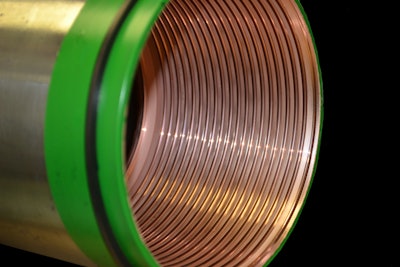

When the two stainless steel parts of a threaded coupling are in direct contact with one another, the constant friction can result in the galling of the metal, wherein the threads seize or abrade - this can cause the joint elements to jam or damage the threads themselves.

For parts such as Oil Country Tubular Goods (OCTGs), this threatens leaks and oil blowouts and can often halt the production processes that the parts are responsible for. And so, the economic effects can be more than simply getting the parts replaced or repaired, which is increasingly undesirable at a time when oil and gas supplies are as low as they are.

Newly manufactured stainless-steel couplings at risk of galling and seizing need a thin layer of copper coated onto their threads. These threaded connections, often called premium threaded connections, are an attempt to improve the American Petroleum Institute's standards for threaded pipes and couplings used in OCTGs.

These oil and gas pipes can be very large in size and the threads that need to be plated are at the ends of the pipe. Therefore, standard tank plating is impractical and, in most cases, impossible. Due to their fragile nature or risk of compromise, there is no margin for error for parts used in this industry and it is required that they undergo a selective plating approach.

Selective plating is a portable electroplating method used to enhance, repair, and refurbish localized areas on manufactured components, allowing for the electrolytic coating of localized surfaces without electroplating tanks. As an industry leader in selective plating, companies across the globe have relied on SIFCO ASC to coat their threaded connections for many years.

SIFCO ASC

SIFCO ASC

Consistency in the copper plating of premium threaded connections

The two leading oil field thread design licensors, VAM and Tenaris, have recently instituted programs to establish a standard procedure for qualification, evaluation, and acceptance of copper selective plating. This procedure requires operators to receive formal and specialized training and certification from an "approved selective brush plating vendor" to apply selective copper plating to the premium threaded connections provided by VAM and Tenaris.

In response to these new specifications, SIFCO ASC, the global leader in selective electroplating and anodizing services, has developed its selective plating certification: Copper Select®. Having received approved vendor status by both licensors, SIFCO ASC is sanctioned to train and qualify operators from around the globe in selective plating methods in line with the VAM and Tenaris specifications.

SIFCO ASC has been offering training courses since their inception. Indeed, Copper Select® was added and qualified in 2013 to the portfolio of training courses, which includes the Basic Training Course and the Cadmium/Zinc Nickel Certification Training Course, amongst others. All these training courses can be available worldwide by SIFCO ASC either at their facilities in Cleveland, Ohio and or on-site at the customer's location of choice.

Passing SIFCO ASC's Copper Select® Certification requires the completion of a weeklong training course and submitting qualification samples for approval. Upon completing the process, the licensee will be permitted to selectively plate copper onto Premium Threaded Connections via the technique taught in SIFCO ASC's Copper Select training course. However, to maintain the integrity of the Copper Select® process, qualified licensees will be audited annually by SIFCO ASC themselves.

Acquiring approved selective plating certifications

Parties interested in acquiring the Copper Select® Certification must enter into a three-year licensing agreement with SIFCO ASC, purchase a basic set of equipment tailored explicitly to plating threaded connections, and consistently monitor and measure the results to make sure that the standards expected within the certification are met. To keep the highest quality standards, operators will need to recertify before the end of the three-year period. Additionally, the accreditation is location-based, meaning that organizations with multiple locations, must acquire the Copper Select® Certification for each site.

Suppose an operator has not attained the Copper Select Certification or any other VAM and Tenaris-approved training. In that case, they will not be permitted to work on the premium threaded connections provided by either licensor, which can, in turn, cause production to grind to a halt. Completing the Copper Select® Certification ensures the highest standards of selective copper plating for parts used in the oil and gas industry. At a time when there is increased pressure for this industry to succeed, production problems mustn't be a result of improper processes in part manufacture.

SIFCO ASC's Copper Select Certification guarantees that selective plating is achieved in line with the SIFCO Process, which will provide the highest standards as the industry leader in selective electroplating. This means that oil and gas onshore and offshore procurement can go forward without any doubts.

For more information, visit https://www.sifcoasc.com/training.