Enterprise 3D printing is ascending the Slope of Enlightenment. Gartner placed it there on its Hype Cycle curve in 2013 and it has been marching toward the Plateau of Productivity annually.

That’s quite a journey since 2012 when it was perched atop the Peak of Inflated Expectations along with its kin: Consumer 3D Printing. So how can we overcome hype and get Enterprise 3D Printing to reach its productive place on the plateau, liberated from hype? How can we accelerate its hype cycle?

First, for enterprise or industrial applications, let’s stick with calling it Additive Manufacturing (AM). It will help choke the hype if we have language different from the “Consumer 3D Printing” market.

Now for the strategy… The southern California MEP Center, CMTC, recently partnered with UC Irvine to develop training on AM technologies, its industrial applications and its return on investment. Last week, a dozen staff from MEP Centers across the country convened at UCI to inaugurate that freshly developed training for three days of intensive, immersive learning.

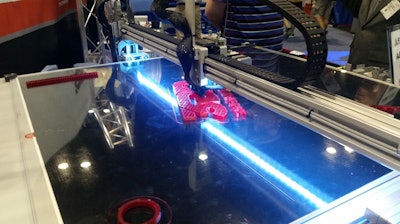

Topics included the pros and cons of each, when to use which – and importantly, how small and mid-sized manufacturers (SMMs) can leverage it. The MEP Center staff learned the difference between the reality and the hype; and came to understand the strengths and weaknesses of each technology and which materials are used by each. We dabbled in solid modeling enough to design parts and repair the design files and then print them on different equipment types. We also gained a good appreciation for the diversity of applications for AM throughout the product development lifecycle.

It was through this recognition of different applications, in the context of understanding the AM technologies, that MEP Centers will be most influential in helping SMMs adopt AM where and when it makes sense for them. Through sharing many case studies, we learned how they can help demonstrate a product concept to an investor, a focus group or senior management. We learned how AM can produce tools, fixtures, molds, jigs and models to support manufacturing processes. Of course, we also reinforced the notion that AM can produce high-value, unique parts (lightweight designs or customized or one-off parts).

But most importantly, the group is forging a Community of Practice, a collaborative group of people who share an understanding of the value that AM can bring to a variety of situations and who each others’ expertise and experience in the AM space for manufacturers. Our community is now poised to continue to learn, support each other through new challenges and projects, and eventually become a national benchmark for other MEP Centers.

As the MEP staff in the AM Community of Practice continue to develop understanding and comfort with AM, they can work more effectively with their SMM clients who have a need for AM. Together, they will trek up the Slope of Enlightenment. The Community of Practice will grow and develop strong AM expertise throughout the MEP network for the benefit of SMMs.

Eventually, we will see “Enterprise Additive Manufacturing” coast along the Plateau of Productivity. At that time, everyone will come to know AM as another, very important, tool in the manufacturing toolbox.

This blog appeared on the Manufacturing Innovation Blog. For more information about MEP workforce programs, click here.