In this exclusive interview with Joey Mulqueen and Eric Halvorson, industrial automation experts at Digi-Key Electronics, a distributor of industrial automation and controls, we discuss new applications for robots; the challenges manufacturers face when integrating robots; advancements in end effector (robot hand) design; and what the future holds for robotics in industrial automation.

IEN: What are the primary challenges manufacturers face when integrating robotics? How can they address them?

Digi-Key: Most end effectors are pneumatic operated, and most robotics are pre-plumbed for pneumatics. However, not all manufacturers have easy access to air. A way around this is to use electric-based grippers or add a small compressor to the robot itself.

Proper safety precautions are a challenge as well. An integrator or certified individual is required to make sure all OSHA regulations are being followed and up-to-date.

Finally, space can be a problem. Industrial robots can take up a lot of space. One of the ways to get around this is to have the robot perform multiple tasks, which enables the removal of older equipment

IEN: How have new applications influenced end effector design?

Digi-Key: With more medical and food-related tasks, sanitation is an absolute concern. Because of that, manufacturers of end effectors and robotics are becoming more and more washdown compatible.

Robots are also completing more than one task at a time, which often requires more complex end effectors. With the growing need of robotics within the industry, robots are required to perform myriad tasks. This means end effectors need to be capable of multi-tasking.

In an ever more competitive market, quality control can be a key differentiator. To address that, end effectors are being equipped with more and more sensors. These sensors can be used on anything from quality assurance to torque specifications.

IEN: What are the key specifications to look for when selecting an end effector?

Digi-Key:

- Grip Strength: Tied to the weight of the object being picked up, grip strength is also important when determining how fast the robot can move with the picked object.

- Grip Stroke Length: Though a gripper typically doesn’t need to open or close very far to grab or release an object, a large stroke length can be helpful when dealing with a wide range of object sizes and shapes.

- Handling Requirements: Look at the industry. For example, if it is going into the medical industry or food and beverage, it will need to be washdown compatible. If it is going into the electronics assembly industry, it will need to be ESD certified.

- Environmental Considerations: If the robot is going to be welding, can it handle the higher temps? If dust or abrasive mists are a concern, then a more sealed or robust end effector might be required.

IEN: As robots play an increasing role in industrial automation, what advancements can we expect in the next five years?

Digi-Key:

- More involved AI: AI provides robots the ability to complete their tasks while learning more efficient ways of doing so and adapting those lessons to its programming. This also allows them to make simple decisions that humans typically make on a daily basis, thereby freeing the human to take on more complex decision making.

- Increased Speed: Speed enables the robot to increase productivity and reduce cost to the company. However, this doesn’t just apply to physical motion, it also applies to the robot’s ability to make decisions, acquire data, and make faster calculations.

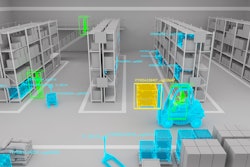

- Increased Safety: Currently, when a customer purchases and installs a collaborative robot (cobot), they come with limited features -- mostly speed reduction and resistance monitoring. However, we are now seeing the industry use third party laser scanners and light curtains to improve safety. Within the next five years, these could very well become standard with cobots.

- Multiuse: In assembly manufacturing, such as consumer electronics assembly, we see a lot of pick-and-place robots. These robots may have suction cups and soldering irons for end effectors. They may also possess the ability to do their own tooling change within the process. In the automotive industry, end effectors not only pick up a windshield, but also apply the adhesive, and then use an alignment sensor to ensure the windshield is properly positioned.

- Robots & Humans Working Side-by-Side: From Exoskeletons to cobots, the industry continues to see more robots and humans working side-by-side. Humans can never be replaced by machines entirely, as complex decisions still need to be made. Machines are, however, essential for businesses to maintain a competitive edge in the market, provide safer working environments for employees while increasing productivity and quality.

IEN: What are some of the interesting new markets and applications using robotics?

Digi-Key:

- Medical: Robots are being used for surgical procedures requiring extreme precision and high repetitive actions. In light of the recent Coronavirus, robotics is being used in developing a cure while working in biohazardous environments.

- Entertainment: In combination with virtual reality (VR) technology, robotics is being used in gaming as well as enhanced theater-like experiences.

- Agriculture & Landscaping: GPS-guided machines, such as autonomous tractors, are being used in agriculture today and those advancements are now becoming commercialized for use in landscaping.

- Construction: With the shortages in affordable housing, predominantly in third world nations, the need for low cost, structurally sound housing is larger than ever. Thus, 3D-printed houses are becoming more and more popular. A concrete 3D-printed house can be done in 24 hours for an estimated $4,000.

Eric Halvorson is partnership marketing manager of strategic programs at Digi-Key. Joey Mulqueen is an applications engineering technician.