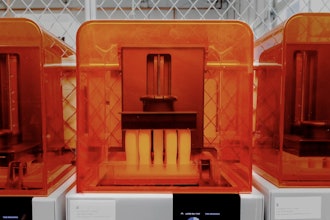

Airbus Helicopters has opened a new 3D printing center at its Donauwörth, Germany, site, significantly expanding its in-house capacity. The company now operates three machines for components made of titanium, four for plastic parts and, as a new element, a machine that can produce components made of aluminum.

Additive manufacturing offers several benefits compared to conventional manufacturing. For example, It can be used for serial production as well as for components for prototypes, such as the electrically powered CityAirbus NextGen and the experimental high-speed helicopter, Racer.

Other advantages of 3D printing include a significant increase in resource efficiency in the manufacturing process and high flexibility. Components with new configurations can be printed as individual pieces or in small series for testing purposes. This also makes the process appealing for building prototypes.

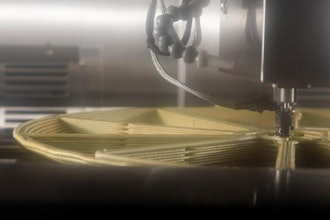

While conventional machining involves milling components out of solid blocks, additive layer printing uses laser beams to melt metal or plastic powders. In this way, the desired shapes are created layer by layer. This makes it easier to produce complex structures than with conventional methods. A conventional manufacturing process requires up to ten times more raw material than the final product, whereas additive manufacturing requires only 1.5 times as much.

Since 2017, Airbus Helicopters has mass-produced more than 9,400 locking shafts for the doors of the Airbus A350, using the additive process as part of the Donauwörth-based airplane door business.

Eleven metric tons of titanium powder have been used in Donauwörth for printing the locking shafts.