What did we learn the last time manufacturing was all but brought to a halt?

While it’s yet to be seen whether the current disruption in our industry will be a necessary evolution or a temporary phase, one thing is becoming more clear; manufacturers need to rethink how they stay operational during unexpected moments.

Can the industry still deliver under this kind of pressure? If the past has taught us anything, the answer is yes—but only if they rethink the tools they're relying on. Every part of the process, from design to manufacture to inspection, now needs to work smarter, faster, and with better flexibility.

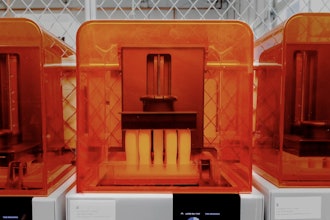

With this, some manufacturers are starting to revisit technologies once considered niche or experimental. One in particular is additive manufacturing (AM), expected to grow by over 23% by 2030 due to its increased influence in industries like aerospace, healthcare, and automotive. No longer seen as just a stopgap when manufacturers are in a pinch, AM can be much more; an AI-enabled approach to stay ahead of disruption in uncertain times.

From Novelty Technology to a Lifeline

In the past, AM was often seen as a novelty—a way to make a cool-looking object or quickly build prototypes or replacement parts in a pinch, sitting on the sidelines of other more critical machines. But the COVID-19 pandemic made something clear -- when global supply chains collapse, tool-less, on-demand production isn’t just helpful, it can be a lifeline.

Whether it was printing masks, jigs, or mission-critical tooling during shutdown, the flexibility of AM gave manufacturers something supply chains couldn’t.

It gave them control.

Now, many aerospace OEMs, defense contractors, and medical suppliers rely on AM not just as a backup plan, but as a core capability for production.

When it comes to the value of AM, it’s not just about speed, but freedom. That’s why the conversation around AM has shifted from a nice-to-have technology to a question of what else it can do. Right now could be another defining moment to reimagine what AM can do—especially as delays and shortages could arise with little warning.

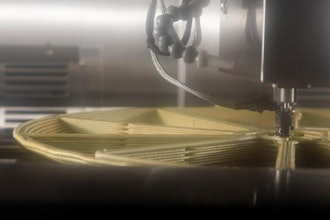

Anything But a One-Size Fits All Technology

On the production floor, AM doesn’t have to work the same for everyone. For instance, we’ve seen some shops using AM to produce their own grippers, jigs and fixtures, replacing broken tools or parts without having to wait weeks for a replacement. When it comes to legacy systems that have limited or no CAD files on hand, engineers can use AM (plus some reverse engineering) to keep equipment running. Even remote and mobile operations are seeing benefits. For instance, The Dutch Navy has equipped ships with onboard 3D printers, enabling critical part production mid-mission.

For smaller manufacturers, AM can become a strategic differentiator. Some are pairing it with CNC to offer hybrid solutions—printing semi-finished metal geometries and finishing them in-house. It’s efficient, scalable, and a smart way to stay ahead without the need for massive retooling.

How AI Makes Additive Manufacturing Even More Relevant

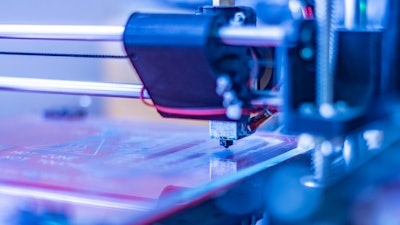

While agility and flexibility are the name of the game for AM, artificial intelligence (AI) is what unlocks its full potential—helping manufacturers move faster, reduce trial and error, and scale production without sacrificing quality.

AI can also help manufacturers proactively identify parts in their supply chain that are vulnerable to disruption—and evaluate whether those parts can be produced additively. By analyzing BOMs and part geometries, AI systems can flag components suited for AM and accelerate the transition from traditional to digital production.

In the design phase, AI can also dramatically accelerate experimentation. Instead of manually testing dozens of iterations, engineers can use AI to run Design of Experiments (DOE) simulations—evaluating how design changes affect strength, fatigue, or thermal performance. Generative design algorithms incorporate AM-specific constraints from the start, ensuring parts are not only functional but also printable. Ultimately, that means fewer iterations and a faster path to production.

On the production side, AI is also transforming quality control. Machine learning models trained on past jobs can predict defects, simulate outcomes, and recommend adjustments before a build begins. These systems monitor material behavior, machine settings, and environmental conditions to define a “process window” where quality is most consistent. Issues can be caught in real time—layer by layer—rather than discovered later on in the process. This “first-time-right” approach results in fewer reprints, less scrap, and faster delivery.

Getting Started Doesn’t Require a Complete Transformation

Getting started with AM doesn’t have to be difficult—and it doesn’t require a complete operational overhaul. A smart place to begin is with parts that are hard to source, frequently delayed, or highly customized. Think legacy spares, low-volume components, or shop-specific tooling.

From there, investing in team training around Design for Additive Manufacturing (DfAM) and integrating digital workflows ensures you’re not just printing parts, but building a smarter, more responsive production system overall. With AI-powered tools supporting everything from design optimization to quality assurance, teams can accelerate learning curves, reduce guesswork, and adopt best practices more quickly.

Learning from the Past

While the pandemic may feel like the distant past, it was a true tipping point for AM—one that set the stage for many of the challenges the industry now faces amid ongoing uncertainty. In essence, AM has been rebranded into a solution that addresses real cost and continuity problems in real time—not just a tool for experimental use.Its North Star is clear; reduce dependency on suppliers, minimize the impact of disruptions, and give manufacturers better control over production from start to finish. A printed part just might save the day.

Mathieu Pérennou is the Additive Manufacturing & Nexus Solutions Director at Hexagon Manufacturing Intelligence.