Phillips Corporation, and Meltio, laser metal deposition technology manufacturer, announce a major advancement in defense manufacturing. Phillips has become the first Meltio partner worldwide to successfully integrate the Meltio Engine Blue into a Haas CNC machine. The milestone marks an evolution in hybrid manufacturing, combining additive and subtractive technologies into one streamlined workflow.

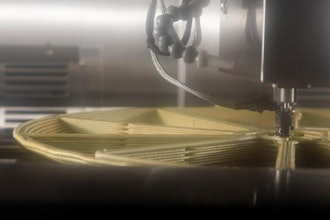

Meltio’s pioneering laser-wire metal 3D printing solution is built around welding wire; the safest, cleanest, and most affordable metal feedstock available. The Meltio Engine Blue empowers defense and industrial manufacturers to elevate their CNC machining capabilities with integrated metal additive manufacturing, providing an agile and scalable solution for mission-critical parts.

Phillips Corporation, a global leader in manufacturing technology and a key partner to defense and government agencies, strengthens its long-standing collaboration with Meltio through this integration. The company is renowned for delivering high-performance solutions that enhance operational readiness, innovation, and competitiveness across industry, defense and academia.

The first Meltio Engine Blue was successfully integrated into a Haas TM-1r, a CNC platform recognized for its precision and reliability, and showcased at RAPID TCT in Detroit, MI, this past April 2025. This hybrid configuration enables defense manufacturers to produce complex metal parts with greater precision, shorter lead times, and reduced material waste—capabilities essential for logistics, sustainment, and rapid deployment environments.

This milestone builds upon previous successful defense collaborations between Phillips and Meltio, including the deployment of Meltio technology aboard a U.S. Navy ship for onboard metal part manufacturing and the U.S. Department of Defense’s adoption of Meltio’s wire-laser metal 3D printing systems to increase supply chain resilience.