How do we as a leading manufacturing nation prepare to capitalize, in every sense, on the increasing maturity and transformative aspects of advanced metal additive manufacturing (AM)? Will the answer come from OEMs and new in-house manufacturing investments? This would certainly buck a century-long trend—so I don’t think so. Or will industry once again turn to contract manufacturers (CMs) and service bureaus to produce new products containing a mix of AM and traditional components?

My prediction is that specialized contract manufacturers, with their turnkey abilities in cutting, heating, polishing and inspection operations, will take the lead. Why? Because they have the true manufacturing expertise to integrate AM with traditional technologies. They are the ones to make and finish parts—under one roof—to exact specifications, and find needed cost efficiencies at the same time.

Service bureaus may evolve into better manufacturers. But their task to date has been to navigate designs through the DfAM limits of conventional AM and to create workable build parameters for less sophisticated systems. Then they largely hand off those discrete AM parts for post-processing and downstream assembly—creating knowledge and control gaps. Is that business model sustainable or necessary?

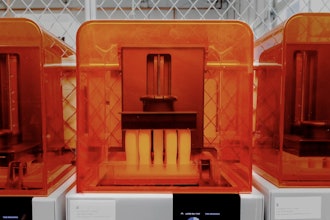

The most advanced metal AM systems remove the need to modify designs to fit the build process—and also eliminate a large share of post-processing as well. For industry as a whole to advance, every future system must address finishing inefficiencies and incorporate automated end-to-end software and controls to handle incoming designs all the way through to a monitored, documented build.

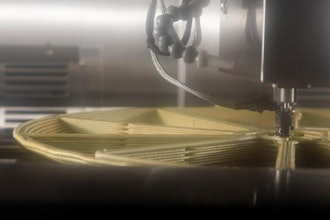

A top CM will know best how to print, cut and surface those designs well before the laser starts its melt path. That’s one way they are uniquely suited to drive performance up and costs down.

A vision of an AM integrated supply chain

For metal AM to fully win acceptance in the challenging fields of aerospace, energy and heavy industry, it needs to be, first, as automated and predictable as CNC operations and, second, highly integrated with every other aspect of production and inspection. I believe it will be a machinist at a CM, not a material scientist in a service bureau, who sets the dials soon for repeatable, series production and on-demand inventory cycles.

One of the talents of CMs in traditional manufacturing is their ability to perfect near-net-shape approaches that reduce waste and cost. Their closed-loop inspection paths, combined with advanced AM process monitoring, will ensure, going forward, that quality is optimized. It’s quality—associated with dimensional accuracy and material integrity—that at the end of the day will drive broad AM adoption and lead to breakthrough products.

To make the next-generation of parts, CMs must also focus on areas of historical strength. Markets they not only understand but significantly helped to shape. We see this happening already, in aerospace and energy. CMs are applying their factory knowledge and mastering new, high-value AM-based turbomachinery parts for aerospace propulsion and energy generation.

With these milestones behind them, CMs are now setting the stage for truly agile and distributed manufacturing. Advanced AM provides the consistent build recipes that work accurately across multiple machines in different locations. Such normalization of flexible AM production will allow OEMs to take their existing supplier model of three to five sources, stay close to global markets, and begin to innovate with less fear of disruption.

One determining factor that will separate out CMs will be their willingness and temperament for very close partnerships and rapid collaboration. Teaming with AM vendors and OEM customers to press ahead on innovation and cost efficiencies will be key to who grows the fastest and maintains high operating margins. With the integration of equipment and a bit of an extra-service mindset, future CM networks will create new markets, stabilize supply chains, address a languishing MRO space, and help fuel economic expansion.