Shifts in predictive technologies, including more advanced analytical software platforms, carry the potential of re-shaping a manufacturer’s approach to predictive maintenance. However, without a strong strategy to supplement it, no technology can be used to its fullest potential.

With that in mind, let’s take a deeper dive into the APPEM approach for predictive maintenance.

First, let’s Assess, or to use a term some of you might be more comfortable with - perform a root cause analysis.

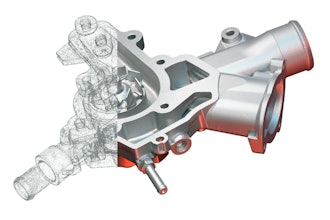

This entails attacking the core of your maintenance issues by leveraging data that spotlights all of the potential factors impacting maintenance touchpoints.

This includes machines, individual parts, your method of data collection and even work order management.

Once you’ve Assessed, now, it’s time to Prioritize. While breakdowns will take immediate priority, ranking them will help establish long-term goals and identify obstacles.

With your Priorities set, it’s time to make a Plan that focuses on high priority projects and highlights tasks that can be automated or prevented. Key to a successful Plan is making sure everyone knows about it.

With the Plan in place, it’s time to Execute. This stage will expose your organization to the frustrations that accompany any new strategy. So embrace these pain points as opportunities to improve.

Finally, with the Plan in Execution mode, its time to Maintain and Modify. While listed last, it’s not a final step.

APPEM is a living, breathing strategy that is most effective when it’s constantly being reassessed and improved.