China is entering a new age of manufacturing with the rise of 'dark factories,' fully automated facilities that operate without any human workers or even lights. Inside these eerily quiet plants, robotic arms weld, cut, and assemble products nonstop. Fleets of autonomous vehicles deliver materials across factory floors without human oversight.

As they are built entirely around machines, these factories eliminate the need for lighting, heating, break rooms, and other human-centric infrastructure.

The result is a system optimized for continuous productivity. It reduces costs, improves precision, and functions at all hours. Powering this new production paradigm is a convergence of technologies such as artificial intelligence (AI), advanced robotics, the Internet of Things (IoT), and dense sensor networks. Together, they create self-regulating ecosystems where machines work together with extraordinary coordination, even with the lights off.

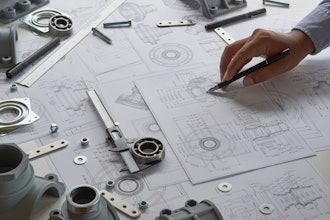

Core Technologies: The Pillars of Automation

At the center of every dark factory is an army of robotic workers. These include not only robot arms that weld and paint but also specialized machines that handle tasks like microassembly, product inspection, and polishing. China has become the global leader in industrial robot deployment. In 2022, it installed over 290,000 units, which accounted for more than half of the world’s total.

By 2023, China’s robot density had reached 392 per 10,000 workers, significantly above the global average of 141. Companies like Foxconn are leading this shift. The electronics giant has replaced over 60,000 workers at its Kunshan factory with robots and aims to automate 30 percent of its operations by 2025. Similarly, BYD, a key player in electric vehicles, has installed robotic systems across its battery and vehicle body manufacturing lines.

Mobile robotics are just as vital. Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) move materials across the floor, reposition tools, and deliver parts. In Jetour Auto’s Fuzhou factory, these mobile robots have cut logistics time by more than 40 percdnt and helped reach an output of one completed car every 100 seconds.

Artificial Intelligence: The Brain Behind the Operation

A dark factory needs more than robots. It needs intelligence that can manage those machines. Artificial intelligence fills that role. AI functions as the factory’s brain by directing robot movements, analyzing data in real time, and making continuous adjustments to keep systems efficient.

At Xiaomi’s smart factory in Changping, the AI platform HyperIMP oversees every aspect of production. It coordinates 11 robotic production lines, monitors equipment health, and reroutes tasks when issues arise. This coordination allows the plant to produce one smartphone every 3 seconds, without manual oversight.

AI is also used in machine vision systems that detect flaws and maintain product quality. These systems can find microdefects that humans would likely miss. Siemens has reported a 99.99 percent product quality rate in its automated facilities, and Xiaomi is reaching a similar level of consistency with its vision-based inspections.

Another crucial role of AI is predictive maintenance. Instead of waiting for machines to fail, AI analyzes sensor data such as temperature, vibration, and motor current. It identifies wear patterns and schedules maintenance before breakdowns occur. The manufacturing sector is expected to gain $3.8 trillion by 2035 from AI adoption. Jetour’s 'Smart Brain' platform has reduced downtime at its Fuzhou facility by more than 60 percent and has improved assembly accuracy across the board.

IoT and Sensor Networks: The Central Nervous System

The IoT and sensor networks act as the nervous system of a dark factory. Every machine is connected through high-speed networks and constantly shares status updates, location data, and quality metrics. This web of data enables real-time adjustments.

Sensors play a critical role in guiding robots. Cameras, infrared sensors, laser scanners, and LIDAR devices help machines perceive their environment. These technologies make it possible for AGVs to navigate in total darkness and for robot arms to place components with micrometer-level accuracy.

All of this data is collected and processed by AI systems, which analyze it to optimize the workflow. At Gree Electric’s 5.5G-enabled smart factory in Zhuhai, this full-stack integration has improved overall production efficiency by 86 percent.

Operational Advantages Driven by Technology

These combined technologies create significant operational benefits. One of the most obvious is 24/7 production. Without human workers, dark factories do not require breaks, shift changes, or holidays. Machines can keep running continuously.

Costs are also significantly reduced. Companies save on salaries, training, and safety measures. They also reduce utility expenses by eliminating the need for lighting, air conditioning, and other systems designed for people. According to the International Energy Agency, dark factory automation can lower industrial energy use by 15 to 20 percent.

Dark factories also deliver extremely high precision. Robotic systems can operate with consistency that surpasses human capabilities. When paired with real-time vision inspection, this leads to fewer defects and higher product reliability.

Another key advantage is cleanliness. Contamination risks drop dramatically with very few humans involved. This is especially important for industries like semiconductors, medical devices, and electronics, where clean environments are critical.

Finally, automated facilities offer resilience. They are less vulnerable to labor disruptions caused by pandemics, strikes, or demographic shifts. This makes them more stable in a volatile global supply chain environment.

The Human Element: Skills for the Factory of the Future

While dark factories require little human intervention on the shop floor, people remain critical to their success. These automated environments still depend on experts to design robotic systems, oversee AI, maintain equipment, and resolve issues. As automation advances, the worker’s role is shifting from manual labor to skilled technical and supervisory positions that support continuous operations.

Essential roles now include AI system trainers, robotics technicians, data analysts, IoT specialists, and cybersecurity professionals. These workers ensure that smart factory systems communicate efficiently, adapt to real-time data, and stay secure. With rising complexity, manufacturing increasingly values interdisciplinary expertise that combines engineering, software development, and data science.

To secure roles in these environments, candidates should highlight skills like Python, PLC programming, SCADA systems, and machine vision. Familiarity with platforms such as TensorFlow, ROS, and MES software is highly regarded. Industry certifications from Siemens, FANUC, or Cisco are also beneficial. Soft skills, including real-time problem-solving and cross-functional communication, are important for leadership and systems oversight.

To meet growing demand, companies and Chinese agencies are investing in reskilling programs. Xiaomi began retraining assembly workers as robotics technicians in 2024, and Gree Electric collaborates with institutes to prepare workers for 5.5G factory roles. The future of manufacturing will depend on how effectively humans are trained to manage, improve, and collaborate with machines.

Case Studies: Xiaomi’s Changping Smart Factory

Xiaomi’s $330 million dollar factory in Beijing spans 81,000 square meters and is one of China’s most advanced dark factories. It is capable of producing 10 million smartphones annually. Inside, 11 robotic lines operate continuously, managed by the company’s proprietary HyperIMP AI system. Vision systems monitor quality, while AGVs handle logistics. The plant can manufacture one smartphone every 3 seconds with zero human involvement on the production floor.

Jetour’s Fuzhou Dark Factory

Jetour’s Fuzhou facility produces SUVs with near-total automation. Over 300 robots carry out welding, painting, tire installation, and even CNC bonding of windshields. It builds a car every 100 seconds and uses its 'Smart Brain' AI to oversee equipment, quality, and scheduling. AMRs and AGVs support flexible logistics, which has helped the factory reach daily efficiency goals faster than previous plants.

Other Industry Leaders

Changying Precision Technology reduced its workforce by 90 percent in one facility by switching to robotics. Output increased, and error rates fell. Meanwhile, Gree Electric’s Gaolan facility uses 5.5G connectivity to support real-time machine learning and ultra-fast response times. These upgrades led to an 86 percent boost in output efficiency.

Strategic Drivers and Global Context

The growth of dark factories aligns with China’s 'Made in China 2025' policy. This strategy aims to upgrade the nation’s manufacturing base by promoting automation and advanced technologies. In 2023 alone, the government invested $1.4 billion in robotics research and development, along with further subsidies to promote AI and smart factory adoption.

China’s labor costs have risen in recent years, making automation economically attractive. At the same time, international competition is increasing. Countries such as Germany, the United States, Japan, and South Korea are also investing heavily in automation. However, China’s scale and state-level support allow it to move faster and deploy technology more widely than many peers.

China’s dark factories are not just prototypes or experiments. They are the beginning of a transformation in how products are made. By uniting robotics, AI, IoT, and sensing technologies into fully autonomous systems, these facilities achieve new levels of speed, quality, and reliability.

The benefits are clear, but the shift raises important questions about the future of human labor and economic structure. As machines become more capable, companies and governments will need to invest in new skill development and social planning. China is leading the way, and the rest of the world is watching as dark factories illuminate the path to the next industrial era.