Researchers Use Giant Gun to Test Hypersonic Flight

The future of hypersonic flight is exciting.

Companies currently building experimental craft are shooting for Mach 1.5 to Mach 2. Boom Supersonic, for example, is now assembling the XB-1 supersonic demonstrator aircraft, which could reach Mach-2.2. However, we need to be ready for the next wave of aircraft that will reach Mach 10 -- that's ten times the speed of sound or 7,672 mph.

Traveling Mach 10, and faster, will present some challenges, so researchers need to study how particular objects and materials will respond to those speeds.

So, the engineers at the Southwest Research Institute in San Antonio, Texas, used a giant gun.

According to the researchers, when an object reaches above Mach 5, the air chemically decomposes around the craft. Some points behind the shockwave get hotter than the surface of the sun. The object typically heats up, melts, and chemically reacts with the air.

Unfortunately, it's impossible to recreate all of these conditions in a wind tunnel, so the researchers used a two-stage light gas gun system to simulate hypersonic flight conditions.

The gun can generate velocities up to 15,660 mph. The system itself is 72 feet long and is normally used to study ballistics.

Right now, the engineers are shooting objects at up to Mach 15 to see how they heat up, melt, and chemically react.

The work could one day help create the hypersonic aircraft of the future by addressing the material challenges now.

Sidenote: At 15,660 mph, that's around the world in just over 1.5 hours.

Robot Flies

Flies are annoying. Thus the phrase "shoo fly, don't bother me." Perhaps you've heard of it.

However, its fly movement that interests the researchers at the Swiss Federal Institute of Technology. Right now, they're studying the way a fly walks because it could lead to advancements in robot transportation. It could also lead to more realistic robot flies.

Flies are capable of climbing nearly any terrain. They have adhesive pads and claws that help them stick to walls and ceilings. If robots could not only improve mobility but also rest on any surface, they could become more energy efficient.

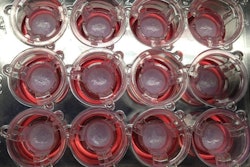

First, they needed to learn more about how flies behave, so the developed DeepFly3D, a motion-capture system for the common fruit fly.

The system recorded a fly walking on top of a tiny floating ball with seven cameras. To keep it in place, they glued the fly's back to a stage.

DeepFly3D learns how the fly maneuver so it can teach robots how to move. And it doesn't just watch. The system predicts what the fly is going to do. If it's right, it confirms its hypothesis or learns from its mistake and evolves.

The study is in eLife Sciences, and the researchers made all of their data available on GitHub.

In the last couple of weeks, the Swiss Federal Institute of Technology has published work on artificial skin, amputees merging with prosthetic limbs, and robotic flies.

Oh, and we're not just talking flies either. DeepFly3D works on other animals as well, even humans.

World's Largest 3D Printer Prints Fully Functioning Boat

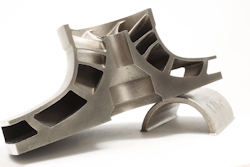

Yesterday, the University of Maine Advanced Structures and Composites Center unveiled the world's largest polymer 3D printer. The printer is capable of printing parts up to 100 feet long, and at a ceremony, they revealed some incredible achievements.

First, they showed off a 3D printed tactical center they printed in three weeks. Next, they showed off a 3D printed boat mold made from PLA derived from corn and nanocellulose derived from wood. The mold helped build the roof of a boat. The material is 100-percent recyclable.

Finally, the team pulled the cover off of a 25-foot long, 5,000-pound boat that was entirely 3D printed.

While it is the largest 3D printer, it doesn't lumber along. The boat took little more than a weekend to print. The researchers started printing the boat on a Thursday at 6 pm, and by about the same time Sunday night, they had a boat.

While many names were considered, including the 3D Mainiac, the multidisciplinary team of researchers and engineers settled on the 3Dirigo. Dirigo, which means "I lead" in Latin, is the motto for the state of Maine.

Overall, the project cost about $40,000.

The boat was outfitted with a 150 HP Mercury motor, christened with a bottle of champagne, and better yet, it floated.

Guinness World Records was on hand to officially recognize the 5,000-pound 3Dirigo as the largest 3D printed boat in the world. The record was previously held by a 40-pound rowboat.

When discussing how such an achievement was possible, one university official said, "none of us is smarter than all of us."