Airbus and STMicroelectronics recently signed an agreement to cooperate on power electronics R&D to support more efficient and lighter power electronics for future hybrid-powered aircraft and full-electric urban air vehicles.

The collaboration builds on evaluations previously conducted by both companies to explore the benefits of wide bandgap semiconductor materials for aircraft electrification.

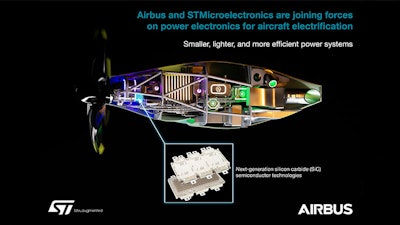

Wide bandgap semiconductors like Silicon Carbide (SiC) and Gallium Nitride (GaN) have superior electrical properties compared with traditional semiconductors like silicon. They enable smaller, lighter and more efficient high-performance electronic devices and systems, particularly in applications requiring high power, high frequency or high-temperature operations.

The partnership will focus on developing SiC and GaN devices, packages and modules adapted for Airbus' aerospace applications. The companies will assess the components by conducting advanced research and tests on demonstrators, such as e-motor control units, high and low voltage power converters and wireless power transfer systems.

According to Sabine Klauke, Airbus Chief Technical Officer, the combination of STM's power electronic expertise with Airbus' aircraft and VTOL electrification efforts will accelerate the path towards the world’s first hydrogen-powered commercial aircraft as well as fully-electric urban air mobility.

Decarbonizing flight requires a range of disruptive solutions that mix new fuel types and disruptive technologies. One such solution, hybrid-electric propulsion, can improve the energy efficiency of every aircraft class and reduce aircraft CO2 emissions by up to 5%. That figure could be as high as 10% for helicopters, generally lighter than fixed-wing aircraft.

Future hybrid and full electric aircraft require megawatts of power to operate. This implies huge improvements in power electronics in terms of integration, performance, efficiency and component size and weight.