Industrial scanning equipment like X-ray machines are used in a wide variety of applications, ranging from non-destructive evaluation looking for manufacturing defects and contaminants to scanning trucks or baggage to ensure safety and security.

X-ray inspection can be used for both process and quality control in automated assembly lines. Only a small portion of the energy generated by these systems is emitted as X-rays; the balance is released as heat. Industrial X-ray systems, which can generate several kilowatts of heat during operation, require cooling of the anode to dissipate this heat for optimized performance and a longer operation life.

Liquid cooling systems (LCS) provide an excellent cooling mechanism to transfer the heat from the system to the ambient environment. Thermal management systems that feature liquid cooling offer higher efficiencies than air‐based heat transfer mechanisms, which translates into higher reliability, reduced field maintenance, greater system uptime and lower total cost of ownership.

Industrial Applications

Non-destructive evaluation has become vital for manufacturers to increase the efficiency of the testing process both from a time and quality standpoint. The automotive industry uses these scanners to inspect new tires, looking for voids and non-compliant materials in the rubber.

Motor block inspection is accomplished much faster through the use of X-ray systems that utilize rotating gantries. Industrial components can be inspected with X-ray scanners to quickly determine material structure and potential defects including cracks, voids and inclusions.

The food and beverage industry uses these scanners in the packaging process for quality control by checking the fill level in containers, and by checking for possible contaminants.

Continuous process control by X-ray inspection can occur on low or high-volume automated assembly lines, looking at welds and solder joints on printed circuit boards.

Safety and security concerns addressed by the usage of industrial scanners include checked-luggage scanners at airports as well as scanners used at major public events such as the Olympics, where companies might require hundreds of new scanners all at one time. Such scanners are also used to inspect trucks and shipping containers as a non-invasive method to examine their entire cargo.

Inspection stations for pipelines, to look at weld joints on large-diameter pipes, address another safety concern. Such inspections need to be conducted many times, as periodic ongoing inspections, to check replacement joints, and in emergencies when a problem is detected. For these reasons, some industrial scanners and their liquid cooling systems must be portable, in order to reach the problem. A potential application for this type of technology is bridge inspection.

Liquid Cooling Systems

Offering optimal temperature stabilization and precise temperature control, liquid cooling systems are self-contained units that recirculate coolant to a predefined set-point temperature. An LCS is able to dissipate a large amount of heat generated by the densely packed electronics in an industrial x-ray system.

Liquid cooling systems offer many advantages over conventional air-cooled systems. LCS provide a higher heat pumping capacity, a better ability to direct the heat away from the source, a more rapid cool down time, and are much quieter. In addition to higher efficiency, LCS provide more reliable operation and require less maintenance.

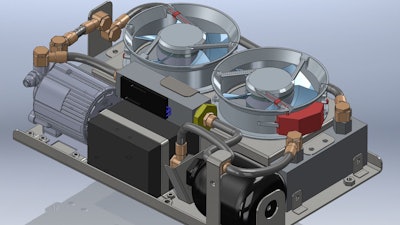

Depending on the industrial scanner’s application, three different types of liquid cooling systems can be utilized. The first is a liquid-to-air heat transfer configuration, where a high-pressure pump recirculates the liquid coolant and an air heat exchanger removes the heat from the liquid circuit, dissipating it to the ambient environment by means of a fan.

The coolant can be water, a water-glycol mixture, or transformer oil, depending on the temperature at the heat source; an oil-cooled system is used when the temperature exceeds the operational temperature limit of the water-based systems.

A second type of LCS uses a liquid-to-liquid configuration, where the pump recirculates the coolant and ambient-temperature water is used in a liquid heat exchanger to dissipate heat on the hot side. The liquid-to-liquid system increases cooling capacity compared with the liquid-to-air system. These systems can be designed to operate with either water or oil as the coolant liquid, depending on the temperature environment.

The third is a compressor-based system, or recirculating chiller, which uses a compressor instead of a liquid heat exchanger to cool the liquid to well below ambient temperature. These chillers can dissipate more heat and thus are more effective in scanning systems where a greater amount of heat is generated.

In addition, x-ray scanning systems may utilize two different types of X-ray tubes, which impacts the type of coolant used in the LCS. With bipolar tubes, the cooling fluid around the anode is in contact with the electrical potential, so it must be a liquid that does not conduct electricity, such as oil.

For a monopole tube, the anode side is grounded and there is no electrical potential, so a water-based coolant, typically a mixture of water and glycol, can be used. Monopole X-ray tubes are more common in industrial applications.

For all types of liquid cooling systems, additional features can add precise temperature control, variable coolant flow rate, coolants with corrosion inhibitors and coolant filtration, as needed. Temperature control of multiple liquid circuits is often required, as is high operational temperature. As with most gantry systems, control of multiple pressure drop settings to accommodate both low and high-pressure conditions may be needed.

Design Objectives

The power level for industrial X-ray systems is between those used in dental applications (where no cooling is required) and medical applications (which require cooling). Industrial scanners may be similar to medical imaging x-ray scanners, but typically they require less power and have lower resolution. Industrial X-rays scanners range in size depending on the application.

Many scanning systems can use liquid heat exchangers, with their smaller form factor and the cooling capacity of up to 5 kW. The larger systems, such as the truck scanners, require very high power. These scanners may not even use X-rays for the power source, but they may instead use alpha or gamma beams. In such cases, the higher heat load may require 15kW recirculating chillers for the liquid cooling system.

Cooling systems for industrial X-ray scanners do not typically have a size constraint, as they are usually stand-alone units that need only be located near the scanners. However, the more compact the LCS can be, the better, making them easier to manage and maintain.

Given their size, the LCS for industrial X-ray scanners tends to be stationary, while the X-ray system can be either stationary or mounted on a gantry. Stationary systems include checked-luggage scanners, where the bags are placed on a conveyor and moved into the X-ray set-up, while a gantry could be used to move the system over the item to be scanned, such as sections of pipeline.

Systems to inspect trucks are constructed so the truck is driven right through the equipment, with the emitter on one side and the detectors on the other side of the vehicle.

There are times when liquid cooling systems need to be portable, for example, on-site inspection of pipelines. In these cases, the weight of the LCS becomes a factor for its mobility. Other important design criteria are simplicity and robustness. The systems can often be fairly simple with little instrumentation, as customers do not want to pay for cooling systems with features they do not need. For mobility and ease of maintenance, a more robust system is desired.

Several companies manufacture industrial X-ray scanning equipment, and typically out-source their LCS needs. They require liquid cooling systems that are reliable and cost-effective. They must offer high performance while being easy to service, minimizing system maintenance and down time for repairs. They expect an LCS lifespan that equals that of the scanner.

Challenges and Opportunities

Many challenges exist in terms of the design, implementation and maintenance of liquid cooling systems for industrial X-ray scanners. However, some of the similarities to medical imaging make the process of developing LCS easier, although there are major differences in the power requirement and the resultant resolution.

The largest difference between thermal solutions for industrial X-ray scanning and medical imaging is the certification. Because there is no patient involved, there is less concern about the LCS – but functionality and reliability are still critical. If the X-ray scanner goes down or is damaged due to liquid cooling system failure, then the customer has no working scanner and faces both a potential shutdown and the cost of repairs.

Some companies that already use scanners are making their own modifications to adapt them to industrial applications. For example, it is possible to modify existing medical gantry systems, to make them simpler and more robust. The liquid heat exchangers and chillers can also be simpler, while still being robust and reliable.

Demands on the LCS for industrial scanners may increase in the future, with up-to-date electronics that provide communication between the LCS and the scanner, while still offering long-life operation and optimum performance.

Thermal Solutions for X-ray Cooling

If an X-ray system goes down, it can shut down the entire manufacturing or security check process. This can significantly impact production and incur large manufacturing costs, or back-up security screening causing massive delays. Robustness of the X-ray and liquid cooling systems are critical to ensure system uptime.

Laird has more than 35 years of experience in providing LCS for non-destructive testing applications, building systems that offer high performance and long operational life across a broad range of product technology platforms and offering exceptional customer support. Their standard and custom liquid cooling systems use both oil- and water-based cooling, with different heat exchanger or chiller technologies.

Laird understands what customers need and can develop solutions custom-tailored to their specific environmental, performance and size requirements, whether the emitter is X-ray, alpha or gamma rays. Their years of experience mean that they have seen similar applications and can respond quickly with customized LCS designs.

Conclusions

Liquid cooling systems offer a high reliability, high performance, cost-effective and robust solution for dissipating the large amount of heat generated in industrial X-ray scanners.

A wide range of standard and custom liquid cooling systems using liquid-to-air, liquid-to-liquid, or chiller-based systems in various sizes and cooling capacities can meet any industrial X-ray application requirement.