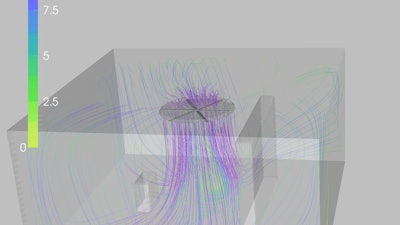

Effective airflow solutions for large spaces were difficult to come by until 1998 when the High Volume, Low Speed (HVLS) fan was invented. Up to 24-feet in diameter, HVLS fans deliver massive amounts of airflow throughout large spaces. Intuitively, big fans produce more airflow than small fans, but the exact amount of airflow and the pathway of the airflow remained somewhat elusive. Potential customers were not able to visualize the benefits of installing an HVLS fan in their space and manufacturers were struggling to help them understand, until the introduction of AirViz. AirViz, an air-visualization program based on computational fluid dynamics, precisely tracks the pattern and speed of airflow in any given space and displays it in a colorful 3D motion video.

AirViz takes the guesswork out of selecting the correct fans, placing them in the best locations, and hanging them at the proper height. The program allows users to harness the power of computational fluid dynamics to understand the airflow solution HVLS fans provide. First, a building’s measurements (height, width, length) as well as its internal obstructions (racking, dividers, equipment) are entered into the program. Fans can then be virtually placed in the space. Utilizing this information, AirViz runs simulations to map the airflow as it travels from the fan, throughout the space, and around obstructions. Users enjoy 3D video animations of the airflow HVLS fans would generate in their space.

Before AirViz, the process of simulating airflow was performed on a single high-powered computer that was often lengthy and repetitive. Airflow simulation requests would come in and be added to a queue. Then engineers would use commercial 3D modeling software to model the buildings and obstructions (racking, equipment, etc.) and place the fans. The engineers would then set up and run the flow simulation on the CFD package of the software. When the simulation was completed (usually the next day), the engineers would load the results and produce still images, animations, and a report. Often the queue would be quite large and the lead-time would grow up to two weeks. MacroAir, the inventor of the HVLS industry category and a leading manufacturer of large size commercial ceiling fans, began exploring the possibility of developing a web application that would somehow submit data to a local server or a cloud server, model the data, render the images and animations, and return the results to the web application for easy access.

Developing the Web Application

Generally, flow simulation can be broken down into three parts: creating the geometry and initial conditions, running the simulation, and post processing the data into a usable form. MacroAir needed to automate these steps, first locally, and then integrate them with a cloud server and web interface. The modeling package that MacroAir was using did not allow for automation so they found an open source CFD platform that they could program to run through all of these steps. The platform was very raw and required a great deal of knowledge of both fluid dynamics and programming languages. While this was a difficulty, it also proved to be a great benefit because MacroAir could adjust the program to automatically simulate our large fans in large buildings.

One major difficulty came when they were programing the portion that creates the geometry. Something was needed that was simple enough that their customers could draw it on a web interface and then have it translated to the cloud server to simulate, yet be versatile enough to account for most of the buildings that need to be simulated. Eventually, MacroAir came up with a building block system. Their web developer put together a simple palate where the customers can draw out rectangles in two dimensions, then specify the height for a three-dimensional building. They can then add any of MacroAir’s fans from a menu and place them where they want. All of this information can be boiled down to a small text file that contains the location, size and type of the blocks and fans. This allows for simple and quick transfer of data to the cloud server and the simulation.

Another difficulty came with determining how to run the simulation. There are many variables that must be chosen correctly to make sure that the solution is accurate, consistent, and fast. These variables include the type of simulation method, size of the mesh (how many little parts the simulation is broken down into), and how each part interacts with each other. Choosing this takes expertise, practice, and some luck. At first they were able to solidify some of these parameters based on their previous experience in working specifically with fans. They also needed to run through examples using trial and error to help insure that the solution was accurate, consistent and fast for a very large set of possible simulations. What MacroAir came up with works very well, and they continue to update and make improvements as they learn more about their customers' needs.

MacroAir recently added the ability to input obstructions. Customers can simulate how racking, equipment, and internal structures influence the airflow from the fan. A report was also added that summarized the data in a PDF form. Among other things, the report shows the average air speed in the occupied area. This is the average speed of all the air from 0 to 6 feet. The report also calculates the perceived temperature difference based on the average air speed and the comfort calculations found in ASHRAE 55. Currently, they are working to implement the ability to simulate the fans at variable speeds and in reverse. MacroAir’s fans are not always run at 100% so this will allow customers to see the flow from their fans at lower speeds.

The Value

With the introduction of Airviz, users are now able to visualize and understand the potential airflow in their space with exact dimensions and place fans and obstructions accordingly. Automated airflow simulations bring MacroAir from manually building out simulations on a local computer to putting the tools in the hands of their distributors to be able to easily do it on their own. A process that previously took two days to two weeks, now only takes 15 minutes to 15 hours (depending on the complexity of the model). This acceleration and increased efficiency gets results to potential customers faster to see how well the fans will work in their space.

Jonathan Hollist is a Research & Development Engineer at MacroAir, and is the developer of the simulation portion of the AirViz Online Tool. For more information, visit www.macroairfans.com.