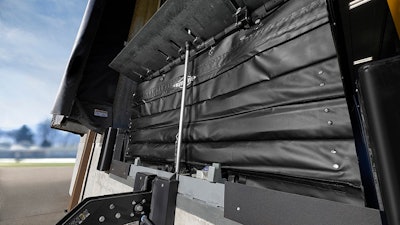

The PitMaster II Under-leveler Seal from Rite-Hite (Milwaukee, WI) helps facilities save energy and keep contaminants out by providing a seal at the “fourth side” of the loading dock opening. Utilizing a main sealing curtain, side seals and filler panels, the PitMaster II seal helps maintain facility cleanliness and improve energy efficiency at the loading dock. According to Rite-Hite, not only does it help deny access to pests and contaminants into the facility and keep debris and dirt out of the leveler pit, it also protects against energy loss by blocking gaps to prevent air flow, while simultaneously creating a thermal barrier beneath the dock leveler to reduce heat exchange through the steel leveler deck. The PitMaster II comes with several innovative standard and optional components:

- Main sealing curtain – The durable black vinyl curtain is secured to the dock leveler and follows its motion to seal the front of the leveler pit from side to side, bottom to top, when leveler is operated. When leveler is stored, PitMaster II keeps sealing the pit even when no trailer is in place at the dock.

- Side seals – Made of durable vinyl and mounted to the pit walls, side seals seal stubborn gaps between the dock leveler toe guards and pit walls.

- Filler panels – HMWPE plates attach to leveler subframe on right and left sides, filling air gaps between the dock leveler and the pit walls.

- Optional components – Lip corner seals, bumper filler pads and bumper covers work together to seal gaps at corners of leveler lip, and between the leveler, dock shelter, and dock bumpers when a trailer is in place.

www.ritehite.com, 800-456-0600