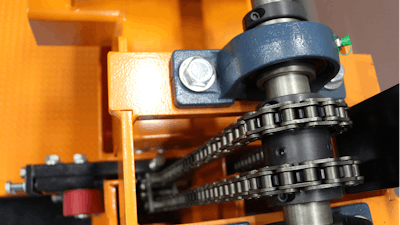

PFlow (Milwaukee, WI) has announced the new Quantum Drive, a lift design that employs two chains, not just one. The results are greater strength, speed and reliability; quieter operation and unparalleled stability. Standard lifts use one chain at each lifting point, which can result in vibration so extreme that the carriage bounces, gates and enclosures rattle and the entire lift shakes. With Quantum Drive, the sprockets on the two chains are arranged so that when one is driving on a tooth, the other is driving between teeth. Effectively, the pulses cancel each other out, resulting in smooth, pulse-free operation. Additional benefits include:

- Safety: All mechanical VRC designs are required by ASME B20.1 to have built-in, carriage-mounted safety cams. In case of a broken or disconnected lifting chain, the cams engage to prevent the carriage from falling. The abrupt stop, however, can be damaging to surfaces of the guide columns, and to fragile payloads. On the Quantum Drive, conversely, each chain can safely support the full-rated load, independent of the other. If a single Quantum chain breaks or becomes disconnected, electronic sensors safely stop the lift, without the abrupt and potentially damaging activation of the safety cam.

- A trapped flange guide system on straddle carriages: VRCs typically have one large wheel inside the guide column at each of the four guide points. If a load is unbalanced, or as loads are moved on and off, the carriage can teeter and rock. The Quantum Drive erases this effect. Its trapped flange guide system uses eight wheels - four on the inside of the column flange, with four partnered on the outside - to eliminate carriage teetering.

The Quantum Drive is now a standard feature on PFlow’s mechanical two-post lifts, and may be added to other models in the future.

www.pflow.com; 414-352-9000