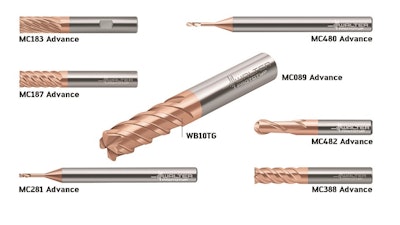

Walter (Waukesha, WI) has introduced its ISO H Advance Line of solid carbide milling cutters, consisting of seven new cutter families specially tailored to the requirements of hard machining (up to 63 HRC). These new cutters include mini and multi-flute, shoulder/slot, ball-nose and high-feed milling cutters which cover the full range of solid carbide milling. The new WB10TG grade achieves long tool life and excellent surface quality, and Walter's performance-enhancing geometry yields high metal removal rates. Suitable for a wide range of applications, the cutters can be applied for large or small components and for various milling strategies, such as roughing, finishing, high-feed milling and for machining 3D contours with the ball-nose mill. Their superior properties make these high-end milling cutters for hard machining particularly beneficial for users with medium-sized batches and high-quality requirements. They are also ideal for users seeking high performance and excellent price-to-performance ratio.

www.walter-tools.com/us; 800-945-5554