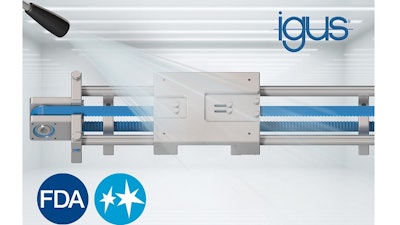

igus (East Providence, RI) has introduced a maintenance-free toothed belt axis specifically designed to improve sanitation in food manufacturing systems. The new drylin ZLW toothed belt axis is based on hygienic design principles and uses FDA-compliant materials.

Cleaning complex machines and systems in food production leads to longer and therefore expensive downtime. The new model can be cleaned particularly quickly and thoroughly - whether with high-pressure steam jets, chemicals or simply running water. This also increases product safety.

The new linear axis is easy to clean because the design engineers at igus followed the guidelines of hygienic design during development. Undercuts in the entire system are minimized where food remnants could accumulate. Likewise, there are no gaps that can occur, for example, if screw heads disappeared into a recess in order to be flush with the surface. Equally important: rounded corners, which ensure that water can flow better during high-pressure cleaning and carry dirt particles along more easily.

Both the shaft end supports, and linear carriages are made of corrosion-resistant stainless steel. The plain bearings, on which the carriage moves over the rail are made of the food-grade triboplastic iglide® A160, which enables low-friction dry operation - without external lubricants, which could become a contamination hazard and pollute the environment.

www.igus.com, 800-521-2747