“Let’s go invent tomorrow instead of worrying about what happened yesterday.” – Steven Jobs

A manufacturer can be innovative in various ways beyond the use of technology. Innovation can include the utilization of new business models, the development of new processes and services, and the enhancement of existing products too.

Technology does support and drive innovation. Technological advancements can allow manufacturers to create higher quality goods faster than before, with less expense and help them realize more efficient operations to become more competitive.

Innovators and engineers are constantly improving upon existing technologies to fulfill unmet needs, provide goods for untapped markets, and most importantly, looking forward to stay ahead of the competition!

So, in that spirit, here are five technologies that are impacting manufacturing innovation. I realize that this is by no means an exhaustive or complete list, so these represent but a few for your consideration:

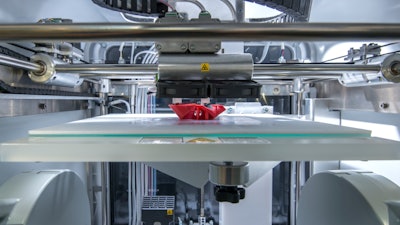

1. Additive Manufacturing/3D Printing

Additive manufacturing was actually developed in the 1980’s, but has picked up more significant interest in the last few years. It covers any and all processes involved in printing a 3-dimensional product, the reason it’s commonly referred to as 3D printing.

Additive manufacturing includes a technique called cold spraying, which involves blasting metallic particles through a nozzle at high speeds, binding particles together to form shapes.

This creates a part by building materials layer by layer through the control of a computer. Because the end result is a high precision replica of an original design, there is less waste during the production process and can save the manufacturer money.

Historically, additive manufacturing technology has been expensive and was typically used by the “bigger fish” in the field. However, recent advancements have enabled additive manufacturing to become more affordable, and it is anticipated to become a common option for smaller manufacturers. 3-D printers will continue to change the manufacturing landscape by creating more efficient ways to manufacture custom parts and goods.

2. Advanced Materials

A report from the President’s Council of Advisors on Science and Technology (PCAST) notes that “almost all the megatrends for the future — energy efficiency or alternate energy devices, new materials to counter resource shortages, next-generation consumer devices, and new paradigms in chemical safety and security — depend heavily on advanced materials” and that these advanced materials “will fuel emerging multi-billion dollar industries.”

This includes advanced composites, which have to date been largely restricted to use in a limited number of high-cost applications. However, efforts are underway to develop manufacturing processes that lower cost and speed production such that advanced composites are integrated into a much wider range of products and applications in the coming years.

3. Cloud Computing

Cloud based computing uses network connected remote services to manage and process data. Life in the cloud will gain momentum, but security concerns must be continually addressed.

Companies are increasing use of this technology across various geographic locations to share data to make better business decisions. Cloud Computing helps reduces costs, improve quality control and shorten production times.

4. Internet of Things (IoT)

Many of us now can’t imagine life before the smartphone…welcome to the idea of a smart manufacturing facility. Smart technology is not brand new, but it is steadily developing into the wave of the future for manufacturing.

Imagine a workplace where connected equipment will be able to communicate via the Internet and computerized manufacturing machinery will be able to “talk to each other” and send/receive notifications about operating conditions. Once a problem is detected, a notification is sent to other networked devices so the entire process can be automatically adjusted.

The end result will be reduced downtime, improved quality, less waste and lower costs. This technology will lead to the development of new types of positions for the manufacturing workforce.

5. Nanotechnology

Nanotechnology deals with matter between 1 and 100 nanometers; a nanometer is one-billionth of a meter. Nanotechnology was traditionally used in the aerospace and biomedical arenas, but is now being used to manufacture lightweight stronger materials for boats, sporting equipment and auto parts, as well as being used in creating personal care items such as eyeglasses.

Nanostructured catalysts make chemical manufacturing processes more efficient by saving energy, reducing waste and will also have increased applications in healthcare and pharmaceuticals.

Staying on Top of Technology

If you’re a small manufacturer, it’s especially important to have a forward-thinking approach and adapt with technology. It can ultimately help companies become more profitable and competitive.

The NIST MEP, MEP Centers, and MEP Partners offer numerous programs and services to help the acceleration of technology for U.S. manufacturers. For more information, check out the Technology Acceleration section of our website.

This blog appeared on the Manufacturing Innovation Blog. For more information about MEP workforce programs, click here.