Imagine you're driving to work on a rainy day, when a distracted, reckless driver hits your car out of nowhere. With a "boom," an air bag deploys faster than you can blink your eyes to save your life.

That air bag deployed rapidly thanks to an energetic material called sodium azide, which generates nitrogen gas during a chemical reaction to inflate your airbag. But what's an energetic material?

Energetic materials include propellants, pyrotechnics, fuels and explosives, and they're used in all sorts of settings.

Uses of energetic materials include flares, matches, solid rocket boosters, gun propellants, hot thermite welding used to fuse materials together, fireworks and the explosive special effects in your favorite action movie.

Energetic materials come in many shapes and sizes, but they're often in a solid form and release a lot of energy through burning or exploding, depending on their shape and the conditions they're operating in.

I'm a mechanical engineering professor who studies energetic materials. Making energetic materials isn't easy, but developments in 3D printing could make customization easier, while allowing for more potential scientific applications.

The role of geometry

How energetic materials are made affects the shapes that they come in and how they release energy over time. For example, solid rocket propellants are made similar to a cake where a stand mixer stirs the "batter," which is mostly made of ammonium perchlorate, aluminum and a rubbery binder, before it's poured into a pan. The "cake" solidifies in the pan while it bakes in the oven.

Typically, rocket propellants have a cylindrical shape, but with a rod in the center. The rod often has a specific cross-sectional shape, like a circle or a star. When the propellant solidifies, the rod is removed, leaving the core shape behind.

The core shape affects how the propellant burns, which can affect the thrust of the motor it's used in. Just by changing the central shape of the propellant, you can make a motor accelerate, slow down or maintain its speed over time.

But this traditional "cake baking" process limits the shapes that you can make. You must be able to remove the rod after the propellant solidifies, so if the rod's shape is too complex, you might break the propellant, which could make it burn erratically.

Designing propellant shapes that make rockets go faster or fly farther is an active area of research, but engineers need new manufacturing methods to create these increasingly complex designs.

3D printing to the rescue

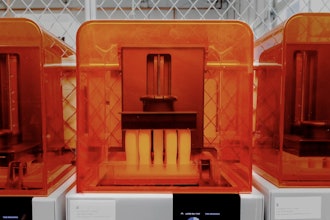

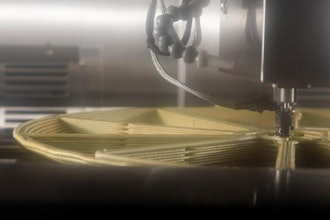

3D printing has revolutionized manufacturing in a variety of ways, and researchers like me are trying to understand how it can improve the performance of energetic materials. 3D printing uses a printer to stack up material layer by layer to build an object.

3D printing allows you to make custom shapes, print multiple types of material in one part, and save money and material.

However, it is very challenging to 3D-print energetic materials for several reasons. Some energetic materials are very viscous, which means it is very hard to squeeze that mixture out of a tube with a small nozzle. Imagine squeezing clay out of a small syringe – the material is too thick to easily move through the small hole.

In addition, energetic materials can be dangerous if handled improperly. They can ignite if there is too much heat during the manufacturing process or during storage, or if they are exposed to a static electric shock.

Recent progress

Despite this, researchers have made a lot of progress in the past decade to overcome some of these challenges. For example, scientists have 3D-printed reactive inks onto electronics to enable self-destruction if they fall into the wrong hands.

Theoretically, you could also 3D-print these inks strategically onto old satellites or the aging International Space Station to break up these orbiting devices into small enough debris that burns up in the atmosphere before hitting the ground.

Many researchers are looking into 3D-printing gun propellants. Modifying the shape of gun propellants could make bullets that can fly farther.

Others have sought to use 3D printing to reduce the environmental impact of gun propellants and igniters that require harsh solvents to manufacture. These solvents are unsafe, difficult to dispose of and can harm the environment and peoples' health.

I showed that it is possible to 3D-print solid rocket propellants that have similar properties to traditionally made propellants. With that research, we now have the opportunity to explore how propellants made of multiple materials burn, which is new territory.

For example, instead of using a rod to made a cross-sectional shape in a propellant, you could 3D-print a highly reactive material that you could add to the center. Instead of having to remove that center material, you could burn it up so fast that it leaves a core shape behind. The reactive material would also add energy to the propellant. This would eliminate the need to use and remove a rod to make a central core.

While much of this research is in its infancy, companies such as X-Bow have been 3D-printing propellants and conducting successful flight tests with these motors.

Finally, several researchers have studied how 3D-printed explosives detonate. When the explosives are printed into a grid-shaped lattice, they react differently when their pores are filled with air or water. This process produces a safer "switchable" explosive that does not react unless it is in a specific environment.

3D-printing energetic materials is still a new field. Scientists have a long way to go before we completely understand how 3D printing affects their safety and performance. But every day, scientists like me are finding new ways to use 3D-printed energetics to serve crucial, and sometimes lifesaving, purposes.

This article is republished from The Conversation under a Creative Commons license. Read the original article here: https://theconversation.com/3d-printing-promises-more-efficient-ways-to-make-custom-explosives-and-rocket-propellants-214126.