WALLOPS ISLAND (VA) – Bioprinting human tissues for implantation in patients to treat injury or disease could be game-changing. However, it's difficult to print soft tissues on Earth because gravity causes them to collapse under their own weight, and scaffolding is required to keep them upright. To remove this hurdle, researchers are going to the International Space Station (ISS).

When Northrop Grumman’s 18th Commercial Resupply Services (NG-18) mission launches to the ISS, it will carry an upgraded version of Redwire Space’s BioFabrication Facility (BFF), a 3D bioprinter capable of printing human tissue. The project, sponsored by the ISS National Laboratory, will pave the way for in-space bioprinting of tissues (and possibly organs) that could one day help patients back on Earth.

The materials needed to make prints using the BFF will follow on a subsequent flight, and the first tissue the bioprinter will produce is a human meniscus, a protective piece of cartilage between the bones in the knee.

Printed tissues could not only be implanted in patients but also used as models for drug discovery, providing new avenues to test therapeutics. “Using the BFF, we can create true tissue-like structures in a better way and larger than you can terrestrially,” said Rich Boling, a Redwire vice president. “We can also use the BFF to print organoids, which could be used to test drug efficacy and reduce the need for laboratory animals.”

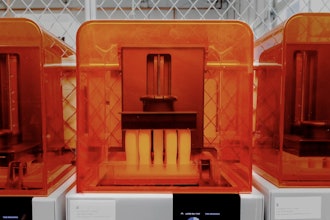

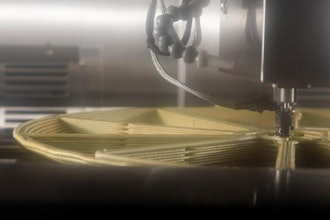

Using a combination of adult human cells and proteins to create human tissues, the BFF dispenses bioinks through four print heads, much like plastic 3D printing. The BFF was first launched to the ISS in 2019, and this upgraded version offers better temperature control to keep the bioinks at the ideal consistency for optimal printing. It also provides new camera views so that ground controllers can better control the prints.

Researchers on Earth have had some success in printing rigid human tissues like bone and cartilage, but soft tissues and blood vessels have proven to be much more difficult to print. That’s due to a combination of Earth’s gravity and the low viscosity of the bioinks used, which require scaffolding for the printed tissues to hold their shape. However, in the absence of gravity, scaffolding is no longer needed for printed structures to keep their correct shape, and the prints can be cured into tissues that could one day be implanted into patients on Earth.

Redwire says the secret ingredient to their success is the BFF’s counterpart, the Advanced Space Experiment Processor (or ADSEP). This adjoining processing facility on the ISS is responsible for culturing and conditioning the cells once they are printed inside the BFF.

The BFF/ADSEP system also enables chemical and mechanical stimulation and potentially even vascularization of the tissues printed. The printed tissues can then be used to create models for drug discovery and to test novel therapies. Printed tissues could even eventually help address the organ shortage.

NG-18 is targeted for launch no earlier than November 6 at 5:50 a.m. EST. The mission will include more than 20 ISS National Lab-sponsored payloads.