Optomec (Booth #433130) will be exhibiting at IMTS 2022 from September 12-17, 2022, at McCormick Place in Chicago.

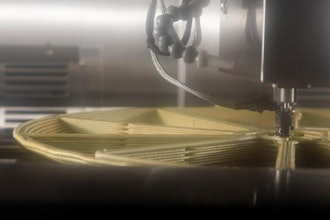

Optomec will be showcasing its latest directed energy deposition (DED) machine, the CS250 live at the show.

The CS250 is the industry’s first DED machine specifically designed to process high volume reactive metals such as titanium.

The use of reactive metals is growing in many industries as the demand for stronger, lighter-weight designs continues to increase.

The system is built on LENS technology which uses a high power laser (400W to 3kW) to fuse powdered metals into fully dense three-dimensional structures. The machine can be used for additive manufacturing and repair applications for parts up to 250 x 250 x 250 mm.

For more information, visit https://optomec.com/3d-printed-metals/lens-printers/low-cost-metal-3d-printer/.