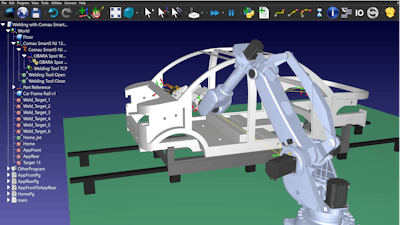

Robotics simulation and offline programming company RoboDK announced a partnership with Comau, a provider of advanced automation solutions and robot manufacturer. The latest version of Comau Roboshop Next Gen software seamlessly integrates with RoboDK, making simulation more advanced.

This integration allows users to easily simulate and program robots using advanced CAD to path features, import 3D Models, detect collisions, integrate with external axes such as turntables and linear rails, support multiple robot cells in the same project, improved integration with CAD/CAM software and use advanced simulation features such as conveyors and grippers. This allows Comau robot programmers to easily use Comau robots for advanced manufacturing applications such as robot machining or 3D printing.

In addition to these technical benefits, the collaboration also introduces support for Realistic Robot Simulation (RRS), providing accurate path and cycle time estimates. This advancement aims to provide businesses with a clear understanding of robot behavior and precise cycle time details, ensuring more efficient and optimized robot operations.

Using RoboDK, it will be possible to create a program in an intuitive way. Then, through Roboshop Next Gen, it can be executed in a simulation with a Virtual Control and then deployed on a real robot.

“Our mission is to build a software platform where users can program any robot arm using the same software, democratizing robot simulation and programming," RoboDK CEO and Founder Albert Nubiola said.