Manufacturing has always been shaped by external disruptions, from cyber risk and sustainability mandates to climate events and labor shortages. Of course, in recent months, one challenge has taken up almost all the spotlight: tariffs.

Tariffs and the resulting shifting trade deals have made long-term planning nearly impossible for manufacturers and distributors.

And the unfortunate reality is, if your supply chain can't flex accordingly, your business won't bend; it'll break.

This fact is driving manufacturers to explore new adaptations, with some proving far more valuable than others.

Moving Beyond the Impossibilities of Prediction

Vendors are now hitting the market with claims that they can use AI to accurately predict changes to tariffs before they're announced. And it can be tempting to buy into the hype of those one-size-fits-all solutions.

But this isn't "Back to the Future." No one can accurately predict what's going to happen before it actually does. Recent events, like the pandemic and the Suez Canal obstruction, highlighted that most manufacturers were forced into reactive decisions, stockpiling inventory, rerouting logistics, and paying premiums for expedited freight.

Some, however, equipped with mature planning disciplines, simulation tools, and diverse supply chains, fared better.

A Smarter Approach

In the real world, where we can't predict tariffs with any greater accuracy than Super Bowl winners, contingency planning will go far further than aimlessly trying to predict disruption specifics. Manufacturers should shift focus to preparedness, so they'll be ready for large-scale disruption, no matter the nature.

That's why scenario planning, supported by sales and operations planning (S&OP) tools like supply chain digital twins and diversified vendor networks, is one of the most effective ways to navigate tariff uncertainty.

Exploring Scenario Planning

Scenario planning is the discipline of planning for different possibilities before disruption strikes. It pushes manufacturers to map out responses to potential shocks, so they aren't forced to improvise under pressure. After all, rushing can lead to critical mistakes.

The result is a set of playbooks and decision frameworks that give leaders options when uncertainty becomes reality.

Common scenarios we plan for might include:

- Tariffs doubling overnight

- Significantly increased or decreased demand

- Shipping channel disruptions (i.e., pirates, canal issues, political unrest)

- Raw commodity price increases

So, instead of scrambling when tariffs shift, leaders can pivot using business plans they've already modeled and vetted.

But remember: You're not just thinking through possibilities. Effective scenarios are dynamic playbooks triggered by live data, such as supplier price changes, trade policy headlines, or sudden shifts in demand forecasts.

So you can confidently answer questions like: What is the tipping point before opening a new facility? When exactly can I start purchasing from the higher-cost domestic supplier (without my boss complaining)?

That's where tools for simulating these scenarios come into play.

Testing Options Before Acting with Digital Twins

Because tariffs ripple through the entire value chain, teams must be able to test responses in advance to ensure alignment.

Digital twins, which are virtual models of factories, distribution networks, or end-to-end supply chains, can help. By mirroring physical operations, they allow manufacturers to test tariff scenarios safely, quantifying impacts on cost, lead time, and margin before acting. They are like "flight simulators" for supply chains. Pilots wouldn't practice emergency landings with real passengers; manufacturers shouldn't bet their margins on untested decisions.

Tariffs move fast and can carry steep costs. Without tools like digital twins, manufacturers are left making uneducated, rushed decisions under pressure. With them, leaders can quantify financial impact, identify the least damaging paths, and effectively rehearse responses in advance — with an estimated potential impact of $37.9 billion.

Expanding and Diversifying Vendor Lists to Stay Agile

Even the best scenarios and simulations can't help if a large-scale change impacts all your suppliers.

When tariffs or disruptions hit, leaders who already have multiple trusted partners can pivot quickly, reduce single-source risk, and maintain continuity for customers. And, by cultivating supply networks across regions and categories, manufacturers can compare options to make confident trade-offs when conditions change.

Of course, diversification requires careful due diligence. New suppliers must meet standards for quality, compliance, and financial health. As such, some modern tech tools come with built-in supplier scorecards and risk assessment dashboards to thoroughly assess fit here. Because when paired with scenario planning and agents, careful diversification can provide both foresight and practical flexibility to keep goods moving, even when tariffs shift overnight.

Get Started Building Agility

Manufacturers can start small with scenario planning by defining key "what if" questions, modeling impacts on costs and operations, and creating playbooks for response. In parallel, they can pilot a digital twin on a single line, machine, or warehouse, using real-time data to simulate changes and test decisions before acting. Leaders can also work to expand and diversify their vetted vendor lists, ensuring that when scenarios play out, there are multiple potential options already in place.

Essentially, scenario planning sets the strategic options, digital twins bring those options to life in a realistic model, and a flexible vendor base provides the practical levers to act quickly.

But keep in mind that ramping up scenario planning, digital twins, and supplier diversification requires a cultural change as well as a technical one. Leaders must model agility and a data-first mindset to help their organizations move from reacting under pressure to staying ahead of disruption. This might include tactics like cross-functional decision forums, scenario drills, or feedback loops.

How to Bend Without Breaking

In modern manufacturing, change is the only constant. Tariffs and trade policy shifts are just one form of disruption, but they're among the most unpredictable and costly.

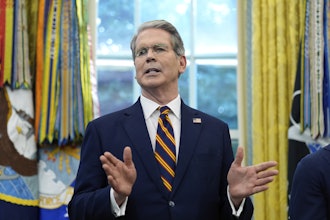

Dag Calafell, Director of Technology Innovation, MCA ConnectMCA Connect

Dag Calafell, Director of Technology Innovation, MCA ConnectMCA Connect

Essentially, instead of simply surviving the next tariff shock, manufacturers that embrace this philosophy will be best positioned for lasting resilience and success.

Dag Calafell is the director of technology innovation at MCA Connect.