Hurricane Matthew set some record storm surge levels when it crashed into the East Coast earlier this year. Cape Canaveral measured wind speeds of over 100 miles per hour, but some of the biggest impact came to the U.S. in the wake of heavy rainfalls that brought flash flooding and inundated houses, businesses and Interstates.

The destruction in North Carolina shook residents, but it came hardly as a surprise: the force and path of the storm were accurately predicted more than a week in advance.

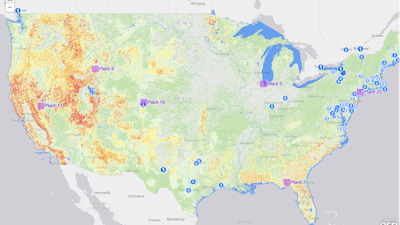

I happened to be in Florida at the CSCMP supply chain conference just prior to Matthew’s arrival and remember watching the actual and predicted path of the storm on a real-time map, accurately projecting coastal impact areas.

Companies with the newest location-aware risk management tools were prepared and knew which facilities and suppliers were potentially impacted.

This real-time risk analysis is part of the biggest trend in supply chain management: the digital transformation. The way we are now able to use data, analysis, and then sharing of the results is transforming business processes into a digital supply chain.

Data has always been a key component of lean supply chain planning, execution and continuous improvement. What is now revolutionizing all aspects of business, is the availability of data at an exponential scale, echoed in big data and the Internet of Things (IoT).

Gartner analysts proclaimed at a recent Supply Chain conference in London that revenue from digital business will double in the next five years – only companies committed to implementing digital workflows will survive the digital race. While the overall direction is clear, the rules in this contest are not so well defined and there are a number of hurdles.

One main challenge is that vast data availability alone cannot transform operations; it may actually cause confusion and overwhelm managers and analysts when they need to decide what data is relevant and what data should be ignored.

Another task is the detection of data relationships – what data should be analyzed together or independently?

The simple standard model of input, processing, and output will have to be refined to include additional pre-processing of input data, advanced analysis during processing, and improved ways of sharing the resulting output.

There is not a single tool that can provide this wide array of digital refinement. A key to successful transformation is to deploy tools that interact smoothly with existing systems and complement each other with a broader set of evaluators, analytics, and information distributors. This defines a need to integrate on a technical level into a digital enterprise platform while offering individualized analysis tools that are easy to access throughout the organization and can securely interface with external entities.

A compelling example are location analysis tools that allow for this input data evaluation, processing, and sharing as part of a Geographic Information System (GIS). Almost all supply chain data has a location aspect.

Companies need to define and leverage a location strategy as part of their digital transformation. This will enable the organization to properly interpret data and to get the most out of their investment in a strong digital infrastructure.

Some of the digital innovation-leaders in the industry are companies such as Cisco and General Motors. Both organizations have implemented a location strategy in their supply chains but in very different ways.

Cisco uses a Geographic Information Systems platform for globally automating customer to service depot assignment for sparing optimization, enabling Technical Services to distribute spare parts inventory more effectively. Through improved service territory visibility and accuracy, Cisco has demonstrated significant traction in eliminating coverage overlaps, identifying and removing service gaps, and optimizing the service part delivery network – all while maintaining industry leading Service Delivery Performance.

General Motors uses location analysis for accurate demand forecasting and comparing their channel network performance with demographic data while evaluating competitors and any inefficient overlap in their distribution. Using a location strategy has helped GM to re-emerge as a strong competitor in the automotive market over the last few years. Now the car manufacturer is extending location usage into other areas such as risk management and network optimization.

IoT, big data, and location analysis are all part of a successful digital transformation across all industries. However, due to the globally distributed nature of supply chain operations, this industry has the most to gain from a strong location strategy.

Utilizing the powers of GIS to enable the real-time filtering of excessively large data streams, evaluating relevant information combined with analysis of existing business data, leads to the ability to share new insights within and outside of the organization.

For supply chain management, a location strategy is a key component to achieving a digital transformation.