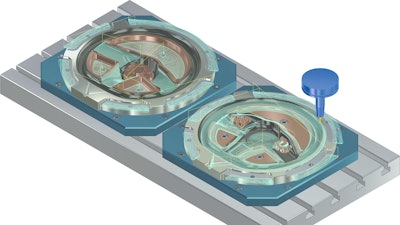

Mastercam (Tolland, CT) recently updated their Mastercam Mill platform to include:

- Stock awareness for selecting 2D toolpaths and allowing tool motion on the top, bottom, or both values of the stock.

- Users can optimize finish passes based on rough stock, providing more efficient and safer tool motion.

- Plunge entry is supported for Dynamic Mill toolpaths.

- Spring passes can be used to create additional finish passes with a spacing of zero between the passes. This can be used for parts with thin material that may have flexed away from the tool.

- All 3D high-speed toolpaths have been streamlined to provide finer control over cut locations.

- High-speed Hybrid toolpaths help avoid partial cuts when a containment boundary is directly on top of a vertical surface.

- Common direction has been added to select toolpaths to keep the tool at a uniform tilt angle to reduce tool and machine motion.

- Dropping has been added to the 5-axis toolpaths and projects the 3-axis toolpath onto the selected surfaces, adjusting the tool vectors to be normal to the surface.