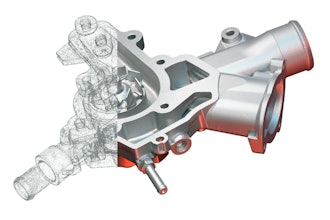

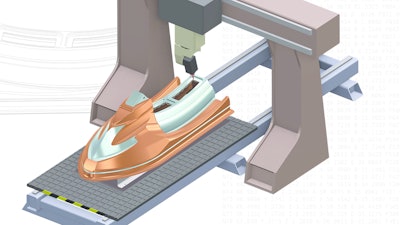

Feature Based Machining evaluates a part’s features and automatically designs an effective machining strategy.

Mastercam

CNC Software (Tolland, CT) has released Mastercam 2018 Router, a new suite of programming tools focused on delivering speed, automation, and efficiency for all machining jobs. Features include:

- Mastercam 2018 for SOLIDWORKS support, including saw toolpaths, block drilling toolpaths, and drawing door and stair geometry.

- Automatic Toolpathing (ATP), which automates the process of assigning toolpaths to geometry for recurrent parts using a machining strategy.

- Tools for control over 2D machining, including contouring, drilling, and pocketing.

- Feature Based Machining, which evaluates a part’s features and automatically designs an effective machining strategy.

- A variety of techniques to rough machine all your parts, including rough cut multiple surfaces, solid models, STL files, or any combination.

- Automated leftover material identification and removal, providing finer finishes. Complete control over toolpath type, tool motion, and tool axis.

- Specialized add-ons for multi-bladed parts (Mastercam Blade Expert) and cylinder head ports (Mastercam Port Expert).

- Complete tab control, including Full Tabs and Partial Tabs.

- Standard nesting delivers fast and efficient way of nesting parts.

- Advanced nesting gives a variety of additional tools, including TrueShape nesting and nesting in scrap material.

- Engraving that can give you the effect of classic hand-carved art using your CNC machine.

For more information, visit www.mastercamrouter.com.