Product Lifecycle Management (PLM) is one of those shape-shifting technologies that constitutes different things to different companies. It often takes a lot of time and effort to get projects off the ground because it’s considered overly complex.

Traditionally automotive and aerospace giants were early adopters and remain committed proponents of PLM, while smaller companies within their supply chains as well as mid-size product manufacturers have mostly remained on the sidelines. More and more firms are experimenting around the edges of PLM, but are falling short of widespread adoption. Oftentimes, these companies don’t know where to start or they don’t have a clear picture of how to properly orchestrate a phased PLM implementation strategy.

Frequently, without an end-game in sight, there is no clear path to achieving business value, which prompts many to put the brakes on implementation plans. Lots of companies simply have their hands full dealing with the constant change surrounding product development that they can’t or won’t take the time to figure out how to evolve PLM to meet their shifting business needs.

For these and myriad other reasons, it’s not uncommon for PLM implementations to stall after initial pilots—the bulk of which stop and start with Product Data Management (PDM). While these companies recognize the strategic importance of PLM and the likely benefits the platform can deliver, they back away after initial implementations. They can often times see the flexibility and the breadth of possible next steps, but are turned away for fear of an overly complex and expensive endeavor that simply can’t or won’t meet expectations.

Yet companies getting caught up in this take are missing out. Once a PLM foundation is in place, there’s ample opportunity to leverage the platform for greater value. Data shows that companies can achieve significantly higher levels of ROI from supplemental PLM projects than they did from their initial implementation. In today’s world where every company is trying to maximize remote communication and get access to relevant product-related data from wherever they may be, PLM is the right platform for the moment.

Beyond the Periphery

It’s not enough to recognize that PLM is the answer—it’s also critical to know how to successfully implement and adopt PLM technologies even as you struggle to get product out the door. While most product manufacturers have platforms in place to share data within their own four walls, their systems break down when trying to make data available to partners within a global supply chain.

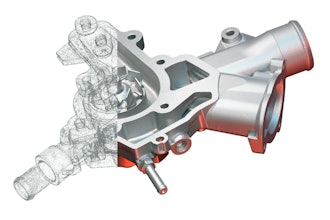

There are well established protocols for sharing visual-product data—think CAD models and simulation data—with suppliers as part of PDM or early PLM implementations, but things get more complicated and data gets lost in translation with so-called drive-by communications processes. This refers to all the pertinent materials, including quotes, certifications, and designs, that are shared with suppliers through stakeholders in the product development process like engineers, sales reps, and procurement. These colleagues fall back on email and spreadsheets to shuttle information and documents back and forth without the proper controls and mechanisms for tracking.

PLM can be the epicenter for those kinds of communications and more. PLM platforms have significantly expanded beyond their initial change management and PDM capabilities, providing functionality in areas like Quality Management, Supplier Management, and Document Management that solves the drive-by communications problem and can greatly aid in compliance. Historically, MES and MRP systems have carried the ball for document management while traditional ERP platforms were the centerpiece for quality and supplier management. Modern PLM platforms have built out capabilities in these areas, closing the gaps between systems and moving closer to the periphery of those other solutions. As a result, PLM can solve more of the problem, simplifying the IT landscape because there’s a decreased reliance on multiple systems, thus less requirements for integration.

While many companies will devote time to discovery—that is, figuring out how they are going to configure and develop PLM technology for a particular business need like quality management, they fail to see the forest through the trees. Without a holistic vision for PLM, they can’t see how the technology will have a positive impact on the greater enterprise so they pull back on deployment, unable to build an ROI that justifies the costs surrounding production selection as well as implementation and deployment costs.

With the right PLM partner, however, companies can cross that bridge without breaking the bank. Creating a PLM road map that identifies how PLM can transform the entire business helps build the business case and creates a phased and manageable implementation strategy that will deliver tangible ROI. Consider the process of change management, for example. Instead of focusing on figuring out how to configure a change management workflow to solve one specific business problem, map out a road map that demonstrates how PLM-driven change management processes can impact the entire organization, from notifying procurement that new parts are coming in to aiding in compliance efforts.

Beyond creating a PLM roadmap, partners can also accelerate time to value for a holistic PLM deployment by helping standardize some of the repetitive customizations that inevitably arise. Partners can also help tie PLM quality, supplier, and manufacturing data to existing engineering processes to streamline workflows and create an environment that can deliver value for all stakeholders, not just engineers tied to one specific process.

PLM is big and powerful, but it doesn’t have to be all-consuming or too costly. With the proper guidance and careful planning, organizations can tap PLM’s simplicity and reach to efficiently solve current problems with an eye towards leveraging the technology to meet the challenges of tomorrow and well into the future.