Slip rings are implemented in a range of industries and their applications are varied. From environmental considerations to operational and performance specifications, custom slip rings tailored to specific application requirements often outclass standard options in effectiveness. Furthermore, making do with a standard slip ring to comply with the demands of specialized, high-performance applications can lead to greater costs and loss of productivity down the line.

The modular nature and design of Orbex slip rings allow for customization to meet precise application requirements without incurring extra costs. And, we offer fast lead times to ensure deadlines are met. This article details some examples where we successfully implemented our custom slip rings.

Industrial Networks

Today’s data-driven production plants need components that can communicate across a wide range of industrial network protocols and quickly transmit critical information. We offer slip rings that support protocols such as Ethernet/IP, EtherCAT, Profibus and more. In addition to this widespread connectivity, our slip rings offer fast data transmission at speeds of up to 1 Gbps.

Satellite Communications

A washdown slip ring with through-hole.Orbex

A washdown slip ring with through-hole.Orbex

For one customer, we designed an electrical slip ring with dual-channel radio frequency (RF) capabilities up to five gigahertz, as well as four-channel Ethernet at 100 megabytes per second. To address space concerns, we put everything together in a compact package and included custom SMA connectors to make installation and integration easier. For other data channel requirements, we supply slip rings with various types of coax cables.

Aerospace

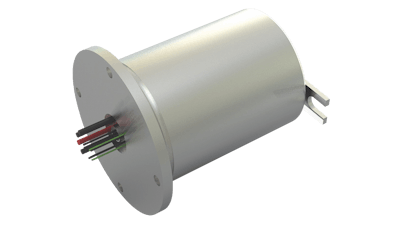

A custom slip ring designed for an aerospace test fixture.Orbex

A custom slip ring designed for an aerospace test fixture.Orbex

Industrial Welding

Our slip rings can be modified to suit industrial welding applications. In one case, we modified a standard slip ring to fit a pipe welding machine. We altered the through-hole diameter and length to accommodate the installation space according to our customer’s exact specifications. As for data and power connections, we also added 12 power channels at 600 volts, 45 signal channels and a high-speed coaxial data channel.

We can include even more signal and power channels by increasing the slip ring diameter. Most of our customers require slip rings that can handle 600 VAC, but we have also designed units capable of 1,000 volts and can go even higher.

Food processing

A washdown slip ring capsule.Orbex

A washdown slip ring capsule.Orbex

Packaging equipment

To maintain high productivity in packaging applications, machines require high cycle speeds and round-the-clock operation. For these reasons, your slip rings must be able to withstand demanding conditions, all while reliably transferring power and electrical signals between your machines and control system. Our slip rings feature proprietary channeled brush technology, creating multiple contact points and reducing contact forces to minimize wear.

Easy Pathway to Modified Slip Rings

We make configuring a custom slip ring a simple process. Our online tool assists in specifying the exact product you need for your application. All of our products, custom or standard, are subject to our fast lead times, so you receive the parts you need in as little as three to four weeks.

For more information, visit https://orbexgroup.com/slip-rings/.