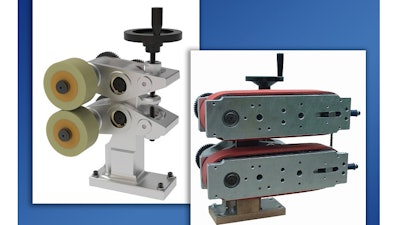

Versa Machinery (Elkhart, IN) introduces Non-Motorized Puller assemblies, in pinch roll and caterpillar puller designs, for a wide variety of downstream handling requirements. With speeds from 0 to 900 feet per minute (fpm) and with a variety of belt or pinch wheel materials available, they are ideal replacements for existing puller assemblies or as components for specialized equipment for unique applications. Specifically:

- “P” series Pinch Wheel feeds are commonly used where materials are not sensitive to pinching pressure and in operations where minimal pulling force is necessary. They are available with roller widths from 2” (50 mm) to 5.5” (127 mm) with roll materials offering different traction and wear characteristics. Versa pinch roll pullers are ideal for the manufacturing of band saw blades, weed whacker line, 3D printer filament, moving and punching rigid profiles and for capturing materials trimmed from the edges of various profile and film extrusions.

- “C” Series caterpillar feeds provide uniform pressure over the entire traction length, which enables greater pulling force without product deformation. Belt configurations range from 2” (50 mm) width X 9” (230 mm) length to 4” (100 mm) width X 18” (460 mm) length. Versa caterpillar pullers are ideal for pulling materials through braiding machines, feeding disc brake materials into grinders, pulling wire and cable, pulling extruded vinyl siding, and more.

A wide variety of belt and pinch wheel materials are available including sponge, gum rubber, silicone, neoprene, urethane, or nitrile some of which are FDA approved. Various durometer ratings are available to suit application requirements.

www.VersaMachinery.com; 574-266-0780