How many machines do you have on your plant floor past their service life? Often, we specify equipment for a 7- or 10-year usage period but continue to use it long after that has passed. In fact, it isn’t unusual to see operational equipment from the 1970s or earlier! But we are only as strong as our weakest link, and outdated equipment is prone to breakdowns. These unplanned downtime moments dismantle our production schedules, drive up overtime work, create missed/late deliveries, and are just stressful. In these high-pressure moments of unplanned downtime, safety incidents and mistakes are more likely to occur. And downtime is expensive. In markets like the automotive industry, it can cost tens of thousands of dollars per minute, directly impacting the profitability of the company.

Component failure, caused by issues like worn belts, misaligned bearings, particle accumulation on fans and unbalanced pumps, can bring production to a halt. But by monitoring the mechanical components and machines, unplanned downtime can be reduced increasing plant productivity. This is accomplished through the processes of continuous condition monitoring or predictive maintenance (PdM).

What is Continuous Condition Monitoring?

In continuous condition monitoring, an asset’s condition is monitored in real time. Typically limits or boundaries are set for acceptable performance values of the piece of equipment. If the values exceed the set high/low limits, an alert notifies the operator or the maintenance technician that something is out of specification.

What is Predictive Maintenance?

In predictive maintenance, an asset is tracked, and condition monitoring data is gathered as it occurs over time. The data is combined with other datasets like historical records, power consumption values, and material lots. Trends are then interpreted, and possible failure scenarios are identified.

Types of Conditions that Can Be Monitored

Vibration measurement is a common way to monitor equipment condition. With spinning mechanical movements like motors, fans, and pumps; increasing vibration is a clear indication of changes. The ISO 10816-3 standard makes this easier to implement by offering guidelines for vibration severity values in common industrial equipment. Worn bearings, stretched belts, and accumulated debris on fan blades can also be detected using vibration. Changes in surface temperature also provide valuable insights, for example an atypical rising of surface temperature can indicate frictional rubbing inside the device. Additional insights can be made from monitoring humidity, sound, pressure, flow and more.

Data Collection Philosophies

Once the conditions to be monitored are identified, you must answer two questions:

- How will data be collected?

- Where will it be stored?

Collecting data can be done in three possible ways: machine control data, bolt-on black-box, and periodic/mobile sampling. The existing machine likely has a PLC/PAC controller with sensors and field devices attached. These controllers can be polled for data at regular intervals over Ethernet. Simple condition monitoring can be implemented with an HMI and event data, requiring no external data storage.

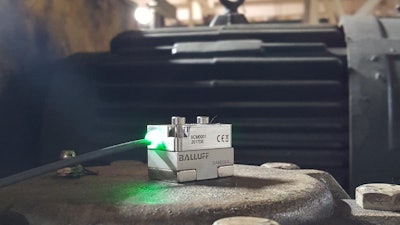

Bolt-on black-box solutions allow for sensors and controls to be added to older equipment for monitoring and data reporting. Protocols like JSON, REST, MQTT, OPC-UA or TCP/UDP are very common and allow for sending data to a database for predictive monitoring applications. Some manufacturers are already executing periodic/mobile condition monitoring to benchmark each piece of equipment every few months. This provides a snapshot in time but is not as powerful as the continuous monitoring offered by the solutions presented above.

Deciding the data storage methodology can be summarized by two choices: local or cloud. Will the data stay inside the company on your servers? Or will you utilize a third-party platform for data? Third parties typically have better access to visualization and data presentation tools, but they come with the liabilities of third-party data management. This decision should always include the cyber-security team and IT department.

A Case Study on Condition Monitoring

Condition monitoring is the one of the most realistic gateways to a smart factory for small to mid-size manufacturers. Equipment retrofits with condition monitoring sensors and data-collection tools do not need to be large capital expenditures with big integration bills. For example, a tier-supplier manufacturer in the US was able to integrate condition monitoring on their main conveyor. Multiple synchronized motors ran the long conveyor system which moved parts around the plant. If the synchronization slipped, the belt would break causing long downtimes — some up to a full day. By monitoring heat and vibration on the gearboxes and setting up ISO 10816-3 benchmarks in the PLC, they were alerted when vibration thresholds were broken. They then determined when a controlled shutdown could occur, reducing the downtime duration by more than 80%.

We can’t scrap all the equipment running past its service life; there’s too much installed that we rely on every day. But we also need it to be reliable. By investing in continuous condition monitoring and predictive maintenance retrofit projects, we can increase plant productivity and reduce unplanned downtime. Remember, if you don’t schedule maintenance for your equipment, your equipment will schedule maintenance for you.

---

About the Author

A Purdue University mechanical engineer who loves to share his passion for automation, Will is a leader at Balluff Worldwide and with the Advanced Manufacturing Industry Partnership (AMIP) in Cincinnati. He speaks from personal experience about the industrial revolution, managing culture change in organizations, bridging the manufacturing skills-gap, and creating value through automation. Be sure to follow Will on YouTube, Twitter & Reddit with the handle #WillAutomate.

Will Healy IIIBalluff

Will Healy IIIBalluff