As a manufacturer, inventory problems are likely top of mind for you these days from the spikes or drops in levels of order demand, or at new levels never before seen, with a new product mix. Or, to be more accurate, you are likely looking for more effective ways to make your plant run smoother handling these spikes or drops, appropriately managing all the order flow in the warehouse as if it was just simply normal operating business…another day at our manufacturing 4.0 plant…"bring it on."

And no wonder with all the recent supply chain disruptions.

Optimizing your ROA is a critical component to overcoming today’s manufacturing challenges, and developing a sustainable competitive advantage. The secret to manage higher Return on Assets is to control inventory based on root causes analysis.

Asset effectiveness is at the top of many manufacturers’ minds these days because margin pressures are forcing manufacturers to do more with less. When prices remain stagnant but costs increase, one of the few ways you can maintain your margins is by getting as much productivity as possible out of your assets.

Then there’s the matter of rising shareholder and investor expectations. Both groups are putting pressure on manufacturers to find innovative ways to elevate performance, cost-effectively. Finally, rapidly evolving market and consumer behavior are forcing manufacturers to be more agile with their resources.

For manufacturing companies, inventory optimization is the key contributor to accelerating your ROA targets both short and long term. Typically, at the plant operating level, there is a cursory understanding of inventories' impact on the company’s financials and return on assets measurement. For any manufacturing leader who is breaking through the ranks, understanding the full picture of ROA and the manufacturing operating contribution is the most valuable driver to long-term health.

Inventory is an asset that costs money to manufacture, procure and store in the warehouse, depreciating away with time…AND why measuring inventory turns is so important. The wrong product mix, too little/too much finished or raw materials will result in a negative impact on the company’s total asset value. This will be reflected in a low ROA as the low productivity chews away at each assets the value.

World-class manufacturing production requires the right product, to be at the right place, at the right time regardless of varying quantities and products. The organization quickly and flawlessly must adjust to changing customer needs, which impact not only local operations and inventory but the inbound and outbound supply chain…in today’s environment, it must all be optimized as quickly and efficiently as possible to meet order requirements and customer expectations.

Warehouse space is at a premium and high movers need to be zoned correctly for minimal travel and easy turnaround. Product placement in the supply chain and mix for a particular production flow design can quickly justify savings, with the current systems, while planning for new technology and IP can really optimize the facility to the next level (where appropriate). A Gemba walkthrough with an experienced “been there done that” manufacturing expert quickly identifies these types of improvements. Many times, new processes or sub/add-on processes develop out of immediate needs without the opportunity for formal design and optimization.

Optimize it, reap the rewards, and continue improving, one kaizen at a time, until you are number one, the gold standard for your industry….Shingo prize bound.

MCA Connect

MCA Connect

ROA Defined

Return on assets is the ratio between your profits and your assets. Assets include your company’s cash, non-cash valuables, marketable securities, property, equipment, and any other liability you have.

You calculate your ROA by dividing your net income by your average total assets. If you have an income statement for your company, generating these numbers will be easy for you. The net income stated on this form factors in the cost of your expenses when evaluating your profit. Your balance sheet will have your total assets listed out.

Your ROA indicates how effectively you run your business. A high ratio shows that your company understands how to use your assets efficiently. A low ratio demonstrates that you are falling behind your competitors.

In a capital-intensive manufacturing sector, another key KPI is the return on net assets (RONA) which can be calculated as:Return on Net Assets = (Plant Revenue – Costs) / Net AssetsThis is used to understand a longer-term perspective of the company's ability to create value at the plant level.

Here are two ways to improve your manufacturing ROA.

1. Make Your Operating Model Agile

If you want to boost your ROA, borrow a page from the folks over in Silicon Valley. They learned a while ago that the key to keeping pace with market pressures and competitors is agility—agility in technology architecture and agility in the operating model.

Manufacturing plants, assembly lines, and shop floors are changing rapidly around the world. The Industrial Internet of Things, artificial intelligence, machine learning, robotics, and more are transforming manufacturing verticals. A key to generating greater ROA is being able to evolve your operating model to leverage these new technologies, processes, and capabilities.

When all around you is chaos and disruption, you must be agile. Build agility into every core capability across your plant and your supply chain, including suppliers, logistics, shop floor, operations & planning, and distribution.

Boosting your ROA requires you to be prepared to disrupt your current ways of doing things, cell by cell, function by function if needed. You must be ready to adopt new technologies, mine your data, and re-train your workforce to meet today’s accelerating pace of change.

2. Prioritize the Initiatives that Deliver the Greatest Return

You have a wish list of opportunities for driving production, cutting costs, increasing productivity, and more. But which opportunities should you act upon today? The ones that promise a high payoff and are efficient to implement.

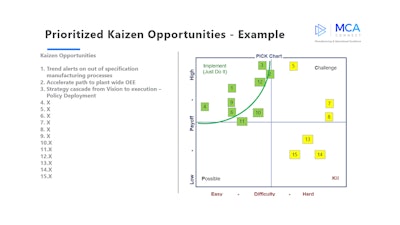

You discover these opportunities by conducting a Kaizen PICK Chart exercise. Here’s how you do it.

Step 1: Identify - List all opportunities, in no particular order, that stands to improve your ROA to one degree or another. Link these opportunities to objectives, such as increasing inventory turns, reduce end-to-end lead time, reduce the cost of poor quality, and increase margin.

Step 2: Prioritize - Create a simple quadrant that illustrates the payoff and difficulty of implementing each opportunity. Each opportunity needs to have a financial value established that ties into the balance sheet of the corporation. Then based on the complexity verse payoff, place each opportunity in the appropriate quadrant

Step 3: Pick Your Winners - Pick the opportunities that promise a high ROA payoff and that are easy to implement. These are your quick wins. But also draw a circle around the opportunities that promise low ROA paybacks and that are hard to implement. Kill these projects and initiatives immediately.

Your PICK Chart will look like this:

This image is taken from NorthStar for Manufacturing, MCA Connect’s business transformation offering that helps you define the roadmap, execution plan, and financial justification to deliver manufacturing excellence to your operations.MCA Connect

This image is taken from NorthStar for Manufacturing, MCA Connect’s business transformation offering that helps you define the roadmap, execution plan, and financial justification to deliver manufacturing excellence to your operations.MCA Connect

Conclusion

Your ROA is a vital KPI that helps you keep track of how well you are running your manufacturing operation, and there are multiple ways to improve your ROA. They include embracing predictive maintenance, making your operating model more agile, and prioritizing the initiatives that will deliver the greatest return.

MCA Connect helps you realize your vision so that you focus on what matters. As an award-winning Microsoft Gold Partner, we provide implementation services and industry-specific solutions to manufacturers in over 24 countries.

Our NorthStar for Manufacturing service is a business transformation offering that helps you define the roadmap, execution plan, and financial justification to deliver manufacturing excellence to your operations. We help you discover the insights and action plan you need to improve your P&L and balance sheet. Learn more about NorthStar for Manufacturing.