Industrial plants and refineries are filled with potential safety risks. Plant managers must reduce those risks wherever possible to ensure safe operation while also maintaining uptime.

Industrial fluid systems should be a primary area of focus, as transporting high-pressure, high-temperature fluids and gases can pose significant risk if systems are not properly designed, calibrated, and operated.

Adhering to proper design techniques and operational best practices can help ensure safe, reliable operation. Here are seven tips every fluid system engineer and technician should know:

1. Do Not Mix Components from Different Manufacturers.

Different suppliers have their own tolerances, quality control systems, design principles, and manufacturing strategies. Therefore, it is not recommended to combine components from different suppliers within the same system, as doing so creates risks for unpredictable performance, environmental releases, safety problems, and increased costs. For example, half-inch fittings from two different manufacturers may not have identical tolerances and, if joined, could create a greater risk for leakage or even a blowout. Selecting one component manufacturer with rigorous standards is the best way to ensure leak-tight seals.

2. Eliminate Potential for Human Error.

Even the most experienced teams can make mistakes. Keeping things simple can help minimize the potential for error.

Be consistent with component labeling. Place detailed tags on hoses and equipment, indicating their function so operators can make appropriate adjustments. Color-coding can also work well, allowing operators to easily identify corresponding fluids or gases flowing through a system.

Installing supplemental components that protect the system from incidental contact with moving objects or people is another simple, effective strategy. Use lockout devices on critical process valves to stop accidental actuation and further boost safety.

3. Select Optimized Components.

It is best to choose the right component for the job rather than make a price-based decision that could risk safety. Because if a safety event does occur, any one-time component savings will not be justified.

Ideal component selection requires thorough understanding of process conditions. For instance, some fluid systems generate static charges. In this case, select a hose with a conductive metal core or a PTFE core with carbon black to dissipate static instead of discharging it through the hose’s core.

Always be sure to purchase system components through authorized channels, as substandard or counterfeit products can compromise a system.

4. Follow the Manufacturer’s Instructions.

Manufacturers provide careful instructions for proper, safe component use. Failure to adhere to the recommended procedures can lead to major trouble down the line.

Following instructions to the letter can help prevent the under-tightening of fittings and other common missteps, including:

- Failure to bottom the tubing in the fitting, not ensuring tubing firmly rests on the shoulder of the tube fitting body prior to tightening

- Failure to check tubes for ovality, scratches, or other defects that may compromise seal tightness

- Failure to compare wall thickness extremes against manufacturer-recommended limitations

- Failure to check for sufficient fitting pull-up with a gap inspection gauge

5. Minimize Complexity.

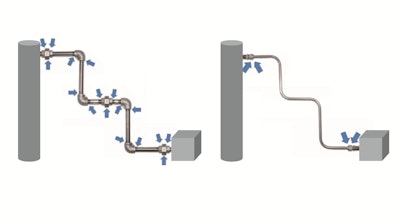

Using fewer overall components is one way to reduce complexity, making it easier to maintain, control, and diagnose a system. For example, using bendable tubing when changing piping runs can reduce the number of components required (Figure 1). Not only is a single, bendable tube easier to inspect, it also eliminates potential leak points.

Figure 1

Figure 1

Elsewhere, complexities can be removed by relying on a supplier who is able to build custom assemblies based on unique needs. Prebuilt assembles eliminate guesswork and are easier to piece together into a completed system. In addition, reliable suppliers will typically back their assemblies with a warranty.

6. Account for Motion and Vibration.

Machine vibration can be an easy variable to lose track of when designing a system, but it is critical to account for to avoid tubing and fitting damage that can lead to leaks.

Adding proper supports can help ensure tubes and fittings will not become fatigued during high-pressure service. Additionally, allowing for a proper range of motion can reduce strain on connection points and other components.

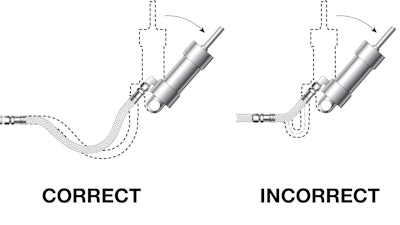

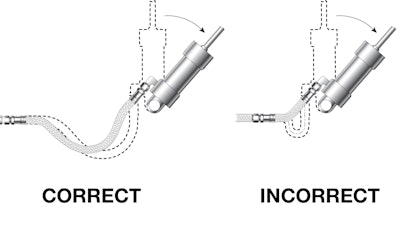

In locations where intense vibration occurs, consider switching to a hose, which may absorb the vibration better than tubing. Make sure to distribute movement over a sufficient length (Figure 2) and account for occasional hose replacement in design considerations.

Figure 2

Figure 2

7. Consider Material Compatibility.

Tubing materials must be compatible with each other and have the right level of hardness to maintain leak-tight connections. Metal tubing should be softer than the fitting components, allowing the fitting to effectively grip the tube. For example, brass fittings are too soft to provide adequate grip on stainless steel tubing.

Designing Safer Systems

None of the above steps should be overlooked. Taking the appropriate precautions and making the right design considerations can help facilities avoid errors, maintain overall system reliability, and most importantly, improve overall plant safety.

About the Author

Ken Backus is Field Engineer, North America for Swagelok Company. He can be reached at [email protected]. He is a contributor to the Swagelok Reference Point blog, where an original version of this article appeared: https://bit.ly/2H1MN5k.