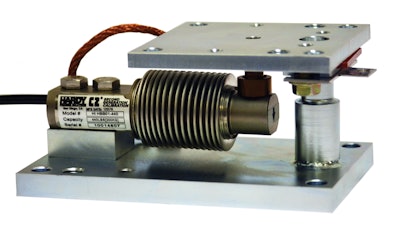

Hardy Process Solutions (San Diego, CA) has expanded its OneMount line to include a model designed for small hoppers, tank weighing systems and bagging machines, as well as other dynamic low capacity applications such as checkweighing and conveyor scales. The Hardy OneMount with Advantage beam sensors allows a vessel or hopper to be installed, bolted and welded using the mount itself. Additional features include:

- Integral spacers that carry the full-rated capacity without the load cells installed, eliminating the need for expensive dummy load cells or welding fixtures typically used to avoid damaging the load sensor during the welding process.

- The 360° checking mechanism, allowing load points to be installed in any direction, with Hardy’s proprietary C2 electronic calibration and matched load cells speeding up the installation process even further.

- Fast and easy maintenance – load cells can be replaced with minimal tank jacking (1/8”), and matched mV/V/ohm load cells can be replaced without recalibration.

- High accuracy and consistency, due to a self-centering rocker that returns the weighing system to proper alignment after experiencing shear forces.

- The innovative precision beam sensor with a capacity of 22 lbs to 550 lbs and a low error rating of just 0.02% of rated output.

www.hardysolutions.com; 858-278-2900