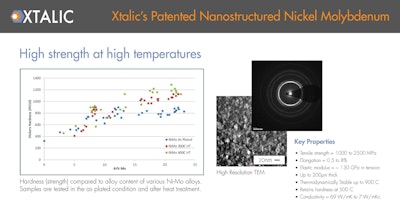

Xtalic (Marlborough, MA) has announced its new, patented, NiMo nickel-molybdenum nanostructured alloy for the manufacture of crucial applications that require strength at high temperature. Xtalic’s new NiMo alloy is ideal for strategic aerospace applications that require superior hardness, strength and durability while being lighter in weight than traditionally used materials.

Compared to nickel and more exotic materials, NiMo alloy delivers thermal stability to elevated temperatures of at least 816oC (1500oF) for longer-life at higher operating temperatures. NiMo-coated components produced through additive manufacturing will feature improved strength, reduced weight and increased efficiency and performance. Moreover, Xtalic can work with designers to tailor NiMo properties to meet the specific challenges of virtually any application — in aerospace or other industries — by utilizing its Dynamic Nanostructure Control and patented Rapid Alloy Design toolkits.