Timing belt replacement is a routine part of machine maintenance that can sometimes cause production delays. To significantly reduce downtime, especially on conveying machines that might require complicated disassembly, PinLock belts can be the perfect solution. New from BRECOflex (Eatontown, NJ) PinLock can reduce replacement time from several hours to less than one hour, depending on the complexity of the machine. To support the production of PinLock timing belts for 2020 BRECOflex will expand their manufacturing capacity to reduce PinLock lead times by 75%.

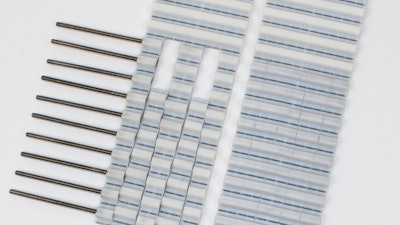

PinLock belts use a precise waterjet-cut finger splice pattern in conjunction with holes in the belt teeth and threaded pins that insert through the splice to connect the belt. It comes in either six pin or ten pin construction, and assembles/disassembles using only a screwdriver.

The PinLock timing belts are ideal for many conveying applications because they accommodate backings or profiles. The belts are currently available in T10, T20, AT10 and AT20, T1/2" and HTD8.

You can view a demo video and get more information at https://bit.ly/2CzfZij.