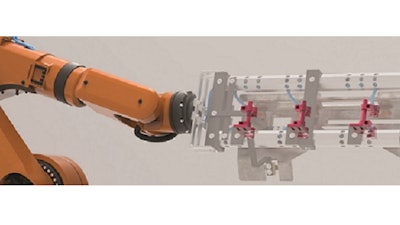

The Modular Automation Tooling system – PMAT – from Piab (Hingham, MA) is now available across the globe, designed to help manufacturers realize secure, flexible and adjustable vacuum gripper/fixture tools for their assembly lines. Machined from high quality anodized aluminum alloy, PMAT is lightweight and easy to assemble on site without welding or special tools. Features include:

- Multiple mounting options, and can be used to design robot end-effector tools, ergonomic tools or fixture tools for any type of automation equipment.

- Both adjustability and rigidity, helping producers to transform their assembly tools to meet their specific needs with minimal design time.

- Ease of maintenance, with spare parts and qualified service support readily available.

- An optional inline filter, and an external check-valve that can be used to meter air flow to the unit, protecting it from over pressurization while saving air.

PMAT has enjoyed particular success in automotive body-in-white (BIW) and stamping assembly areas, but is equally applicable to general assembly within any industry. Attachments include vacuum ejector units based on Piab's energy-efficient COAX technology, providing both grip and release mechanisms.

www.piab.com; 800-321-7422