Although change is a constant in the industrial sector, and our society, as a whole, adjusting to those changes has taken on an entirely new context with the advent of the coronavirus and resulting pandemic. With this in mind, we recently sat down with Terri Hiskey, Vice President of Global Product Marketing for Manufacturing at Epicor Software, to get her take on ways to adjust to a new normal.

Jeff Reinke, editorial director: Prior to the COVID-19 pandemic, what were the most prominent business challenges your manufacturing customers were encountering?

Terri Hiskey, Epicor: The biggest issue was attracting and retaining workers. Some customers have turnovers of 100 percent on their shop floor so they need to not only figure out how to attract new talent, but to put strategies in place—including the technology that these new workers use—to ensure that their new employees have a positive employee experience. Other challenges included needing better visibility into their business processes and the ability to scale and grow.

JR: How has that changed?

TH: I don’t think those things have changed. Many manufacturers needed to move some positions from back office to work from home. Manufacturers that were deemed essential have had to deal more with the issue of not having enough workers. One big change is putting in place safety initiatives like physical distancing and handwashing stations. Visibility continues to be critical.

JR: What software tools, applications or features do you think have helped manufacturers of "essential" products to keepi operations moving smoothly?

TH: Any software that has mobile capabilities has been vastly helpful, as well as software that can be viewed on any device—not necessarily a laptop or desktop. Solutions that can help businesses better understand where their cash is has been important, solutions that provide greater visibility across their businesses is also critical.

JR: Are there certain software tools that can be especially helpful for those transitioning from producing their normal products to those essential in the fight against COVID-19? i.e. Ford transitioning from automobiles to face shields

TH: Yes, things like augmented reality can help businesses visualize how they might have to reconfigure their shop floor to account for producing a different product than normal. Epicor has a solution, Epicor Data Discovery, which helps manufacturers get a real-time view of where production is taking place so that manufacturers can quickly see what equipment is being used and what isn’t so they can more easily identify equipment that has more capacity to produce something that is off schedule for example.

AI technologies like Epicor Virtual Agent can also help answer questions quickly about what products are scheduled where so there is no manual backtracking that has to be done.

JR: What functions of enterprise-level software do you feel will prove most helpful as manufacturers gradually get back to full speed?

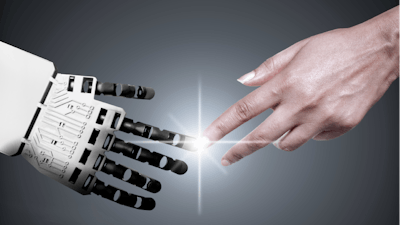

TH: Mobility, artificial intelligence, machine-learning, IoT connected sensors on machines for remote monitoring, analytics and visualization.

JR: If you could provide U.S. manufacturing with one thing - both now and in what we all hope will be a more "normal" future - what would it be?

TH: Permission to let technology help them. Things like co-bots and robotic automation, artificial intelligence and analytics will only serve to improve and push manufacturing forward. This pandemic has proven that U.S. manufacturing can adapt to changes when it becomes an absolute necessity, and technology helped make those changes much easier. Let’s not go back to the way things were … let’s use the lessons we’ve learned and use the technology to focus on moving forward into the future rather than going back to the way things were.