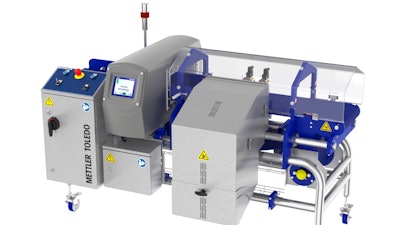

Mettler-Toledo (Lutz, FL) has unveiled its GC Series of conveyorized metal detection systems with features that include:

- A highly configurable design that can be used with a variety of Safeline metal detectors, polyurethane or modular belts, and different reject mechanisms.

- Integrated sensors and reject mechanisms ensure contaminated products are removed from the production process.

- Options range from simple 'stop-on-detection' systems to fully-automated detect-and-reject systems, including pushers and air-blast devices.

- Three levels of due diligence packages, with a suite of failsafe monitoring options, are available to meet specific compliance requirements.

- A modular design simplifies the spare parts inventory because common parts can be used across multiple systems.

- A quick release mechanism means conveyor belts can be removed in under ten minutes, and the tubular, open-frame design and sloping surfaces of the metal detector case minimizes dirt traps, making cleaning easier and faster.