Verta, Inc. is excited to announce its official launch as a high-performance architectural metal coating finisher serving the Midwest and beyond. The company, established in 1985 under another name, has been the exclusive finisher for its sister company, Industrial Louvers, Inc.

Verta is a certified applicator for Valspar and PPG aluminum extrusion formulations. Verta’s standard finish is Valspar’s Fluropon Pure line of coatings. Formulated without the use of perfluorooctanoic acid (PFOA), hexavalent chromium, cadmium, lead, phthalates and other hazardous materials, these coatings were created with material transparency and environmental impact in mind.

“We are really excited about the interest and opportunities we have received from the market,” says Brett Reinhardt, LEED GA, director of operations at Verta, Inc. “Our process is unique and offers significant advantages, including high-quality appearance, durability and sustainability.”

According to Verta, it is the first company of its kind to completely eliminate all types of chromium from its processes without sacrificing quality. After extensive testing, Verta’s chrome-free pretreatment process has proven as effective as hexavalent chromium and more effective than trivalent chromium. All coatings carry a standard 20-year warranty.

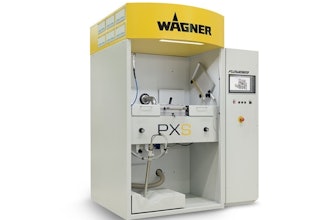

Verta illustrates its commitment to sustainability throughout all of its operations. Its state-of-the art facility and new paint line feature high-efficiency ovens that use a fraction of the energy of traditional ovens. The wash system will use rainwater captured from the building’s roof for the wash process, reducing the amount of water used and processing required to pretreat water for the system. Water is filtered and recycled multiple times through the five-stage wash process, minimizing the amount of fresh rainwater required to fill the system. The company’s new facility was designed and built to be ready for photovoltaic panels in the future. All of these innovations contributed to sister company ILI’s achievement of the International Living Future Institute’s Living Product Challenge Petal Certification.